Blog

How to Use a Tablet Presser for Effective Tablet Making Techniques

In the rapidly evolving pharmaceutical and nutraceutical industries, tablet manufacturing remains a cornerstone of production efficiency, quality, and cost-effectiveness. A significant driver of this effectiveness is the Tablet Presser, a critical piece of equipment that ensures uniformity and precision in tablet formulation. According to a report by Allied Market Research, the global tablet manufacturing market is projected to reach $218 billion by 2025, highlighting the growing need for advanced technologies that enhance production capabilities. The efficiency of tablet pressing directly correlates with the increasing demand for high-quality pharmaceuticals, as well as the trend towards more personalized medicine.

The Tablet Presser offers manufacturers the ability to produce tablets at higher speeds and with better consistency than manual methods. Industry experts assert that proper use of tablet pressing technology can lead to a reduction in production costs by up to 30%, while simultaneously improving product quality and minimizing waste. As the industry adopts more stringent regulatory standards, the role of effective tablet making techniques becomes even more crucial. Understanding the intricacies of Tablet Pressers and their operational methodologies will be essential for manufacturers aiming to stay competitive and comply with evolving regulations in today's market.

Understanding Tablet Pressers: Key Components and Their Functions

Tablet pressers are essential equipment in the pharmaceutical industry, designed to transform powdered substances into solid tablets. Understanding the key components of a tablet presser, such as the hopper, punch and die system, and compression mechanism, is crucial for optimizing tablet production efficiency. According to a report by the International Journal of Pharmaceutics, the proper selection and maintenance of these components can significantly influence the final product's quality, including hardness, dissolution rate, and uniformity.

The hopper serves as the feeding mechanism, holding the granulated material until it is ready to be compressed. The punch and die system plays a pivotal role in shaping and compressing the tablets, with formulations often requiring specific configurations to achieve the desired tablet characteristics. A study from the American Pharmaceutical Review indicated that variations in punch design can affect the density and disintegration time of the tablets, underscoring the importance of precise engineering in component functionality. Additionally, the compression mechanism, which can be either single-sided or double-sided, determines the speed and efficiency of the manufacturing process, further highlighting its critical role in the overall tablet making technique.

Tablet Pressing Efficiency Analysis

Types of Tablet Pressers: Rotary vs. Single Punch Press Machines

When considering tablet pressers for tablet manufacturing, it’s vital to understand the two primary types:

rotary and single punch press machines.

Rotary press machines are acknowledged for their efficiency and high output rates, making them ideal for

large-scale production. According to a report from Research and Markets, the global tablet press market is

expected to grow significantly, reaching over $1 billion by 2025,

driven largely by the increasing demand for high-speed efficiency found in rotary presses.

In contrast, single punch presses, which are often used for smaller production runs or research and

development purposes, provide more flexibility in terms of formulation and material adjustments. They

tend to be more cost-effective for batch productions, as they allow operators to modify parameters easily

without the need for extensive setup times. According to industry analyses, while single punch presses

account for a smaller market share, their versatility and suitability for niche applications ensure their

continued relevance in the tablet manufacturing sector, with growth projections indicating a

steady increase in their operational usage within specialized areas.

Effective Techniques for Tablet Formulation and Material Selection

When formulating tablets, the selection of appropriate materials is crucial to achieving the desired characteristics of the final product. Excipient selection plays a vital role, as it can affect the stability, dissolution rate, and bioavailability of the active ingredients. Common excipients include binders, fillers, disintegrants, and lubricants, each serving specific functions that contribute to the overall effectiveness of the tablet. Ideal materials should ensure compatibility with the active pharmaceutical ingredients (APIs) while offering desired mechanical properties, such as hardness and friability.

Moreover, understanding the properties of various formulations can enhance tablet-making techniques. Granulation, for example, is a key process that influences the flowability and compressibility of the powder blend. Choosing between wet granulation and dry granulation methods depends on the nature of the materials and the desired tablet characteristics. Additionally, incorporating techniques such as direct compression can reduce processing time and simplify manufacturing, which is particularly beneficial when working with potent APIs. Strong attention to detail in material selection coupled with efficient tablet-formulation methods paves the way for developing high-quality tablets that meet specified performance parameters.

Optimizing Tablet Compression: Pressure and Speed Considerations

When optimizing tablet compression, pressure and speed are two critical factors that directly influence the quality and integrity of the final product. Applying the right amount of pressure ensures that the materials are adequately compacted, forming a uniform tablet that exhibits consistent hardness and dissolution characteristics. Insufficient pressure may result in weaker tablets that crumble easily, while excessive pressure can lead to tablet fracture or a compromised release profile.

The speed of the tablet pressing process also plays a crucial role in optimization. High-speed compression may seem efficient, but it can introduce variances in tablet weight and hardness. A balanced approach is essential; therefore, monitoring the speed at which the tablet press operates can prevent quality issues. Slower speeds allow for better control over the compression process, reducing the risk of defects.

Tips:

- Regularly calibrate the tablet press to ensure that pressure settings are accurate, fostering optimal compaction.

- Conduct routine tests to find the sweet spot for pressure and speed combinations—performing trial runs can help identify the best parameters for your materials.

- Observe the tablet formation closely during initial runs, making adjustments to pressure or speed as necessary to achieve the desired tablet characteristics effectively.

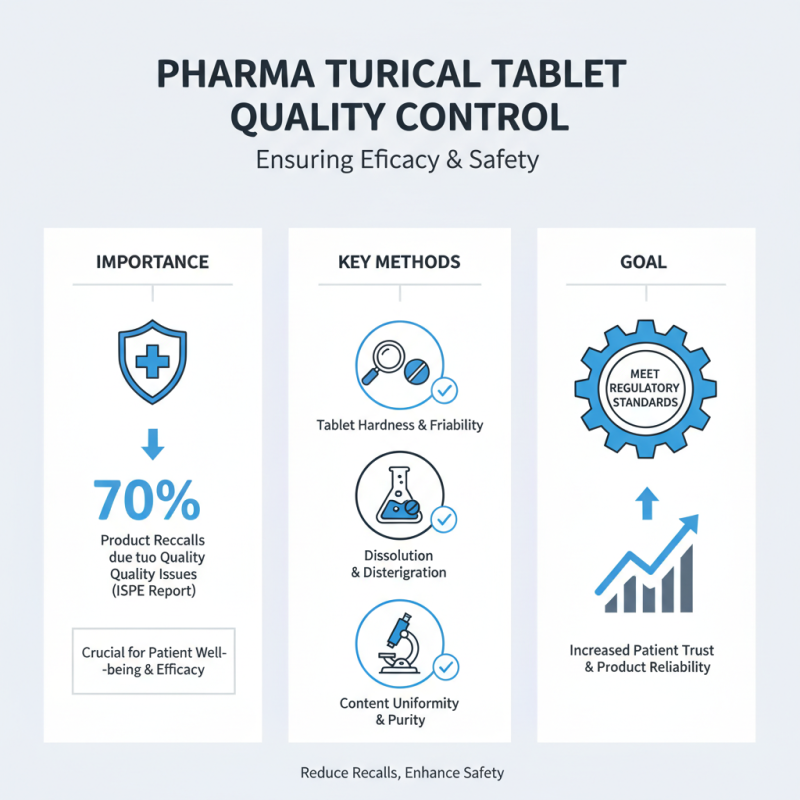

Quality Control in Tablet Production: Testing and Validation Methods

In the highly regulated pharmaceutical industry, ensuring the quality of tablets is crucial for both efficacy and safety. Quality control in tablet production encompasses a range of testing and validation methods that are designed to meet stringent industry standards. According to a report from the International Society for Pharmaceutical Engineering (ISPE), around 70% of product recalls are attributed to quality issues, highlighting the importance of effective quality control systems in the manufacturing process.

One of the foundational elements of quality control involves in-process testing, which includes monitoring parameters such as tablet hardness, disintegration time, and uniformity of weight. The U.S. Pharmacopeia (USP) provides specific guidelines that manufacturers must adhere to, which states that tablets must demonstrate a disintegration time not exceeding 30 minutes to ensure proper absorption in the body. Furthermore, validation methods like process validation and cleaning validation are essential to demonstrate that the manufacturing process consistently produces a product that meets quality standards. A study published in the Journal of Pharmaceutical Sciences indicated that incorporating continuous process verification can significantly enhance the reliability of tablet production by identifying variations in real time, thus minimizing the risk of non-compliance.

Additionally, stability testing plays a pivotal role in quality assurance. The International Conference on Harmonisation (ICH) outlines protocols that determine how tablets behave over time under various conditions, ensuring their potency and safety for consumers. By adhering to these comprehensive testing and validation methods, manufacturers can uphold product integrity and reduce the likelihood of costly recalls and regulatory sanctions.

Related Posts

-

Ultimate Guide to Choosing the Best Tablets Press Machine for Your Production Needs

-

How to Optimize Your Production Efficiency with a Tablet Presser for Maximum Yield

-

How the Best Tablets Press Machine is Shaping the 2025 Industry Tech Landscape

-

Mastering Natoli Tablet Press Techniques for Optimal Performance

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

The Evolution of Tableting Machines in Modern Pharmaceutical Manufacturing