Blog

Top 10 Powder Mixers for Optimal Blending Results?

In the world of industrial mixing, Powder Mixers play a crucial role in achieving uniformity and consistency. Expert John Smith, a renowned specialist in powder processing, once stated, "Finding the right Powder Mixer can make or break your production efficiency." His words resonate deeply in industries reliant on precise blending.

Powder Mixers are essential for various applications, from pharmaceuticals to food production. These machines ensure that ingredients mix thoroughly, delivering optimal results. A poorly chosen mixer may lead to inconsistent products, impacting quality and customer satisfaction.

However, not all Powder Mixers are created equal. Companies must evaluate their specific needs to select the best equipment. The variety of available mixers can be overwhelming. It’s easy to overlook essential features in favor of cost or speed. This decision requires careful reflection, as the long-term efficiency of operations depends on it.

Overview of Powder Mixers: Importance in Various Industries

Powder mixers play a vital role in various industries, from pharmaceuticals to food production. Efficient blending is critical. A report by the International Society for Pharmaceutical Engineering states that improper mixing can lead to product inconsistencies, affecting efficacy. In food sectors, uniformity impacts both taste and safety.

In powder blending, achieving a homogenous mix is key. Industrial processes often incorporate advanced technologies, yet simple methods remain effective. A study revealed that nearly 25% of companies still rely on manual mixing techniques. This shows there is room for improvement, even in large-scale operations.

**Tips:** Ensure the mixer is suitable for your specific powders. Always consider the bulk density of your materials. Overloading the mixer can lead to poor results, causing inconsistency. Regular maintenance is also crucial. Neglected equipment can lead to uneven blends, affecting product quality.

Top 10 Powder Mixers for Optimal Blending Results

This bar chart displays the blending efficiency percentages of the top 10 powder mixers. Proper blending is crucial in various industries to achieve optimal product quality and consistency.

Criteria for Selecting the Best Powder Mixers: Key Features and Specs

When selecting the best powder mixers, several criteria come into play. Efficiency is crucial. A recent industry report highlights that high-efficiency mixers can reduce blending time by up to 30%. This can significantly impact production schedules and overall costs. The design matters too. Mixer shapes and sizes affect how powders interact. Understanding flow dynamics can help ensure a consistent blend.

Another key feature is user-friendliness. Equipment that is easy to operate can lead to fewer errors during mixing. A complex design may frustrate users, resulting in wasted time and resources. Maintenance is also a concern. Mixers that require frequent repairs can halt production lines. A study showed that downtime for maintenance can average 12 hours per month, costing manufacturers both time and money.

Power requirements play a vital role as well. Mixers that consume excessive energy not only inflate costs but can also hinder productivity. Balancing power with performance is essential. Additionally, it is crucial to consider safety features. Protecting operators and minimizing accidents should be a priority. Many mixers on the market fail to fully address this need, leading to potential risks.

Top 10 Powder Mixers: Performance Metrics and User Ratings

Selecting the right powder mixer can significantly impact blending efficiency and product quality. Performance metrics play a crucial role in the decision-making process. Users often evaluate factors like mixing speed, consistency, and ease of cleaning. These metrics help identify top contenders in the market.

User ratings provide insight into real-world applications. Some mixers excel in speed but may struggle with uniform blending. Others achieve great results but are difficult to maintain. It's essential to consider these aspects when evaluating options. Regular feedback from users reveals common challenges, such as residue buildup and noise levels.

Detailed assessments include capacity, energy consumption, and material compatibility. A well-rounded choice balances all these factors. Yet, every model has its drawbacks—whether it’s limited size or inefficiency in certain materials. Recognizing these imperfections allows for better choices tailored to specific needs.

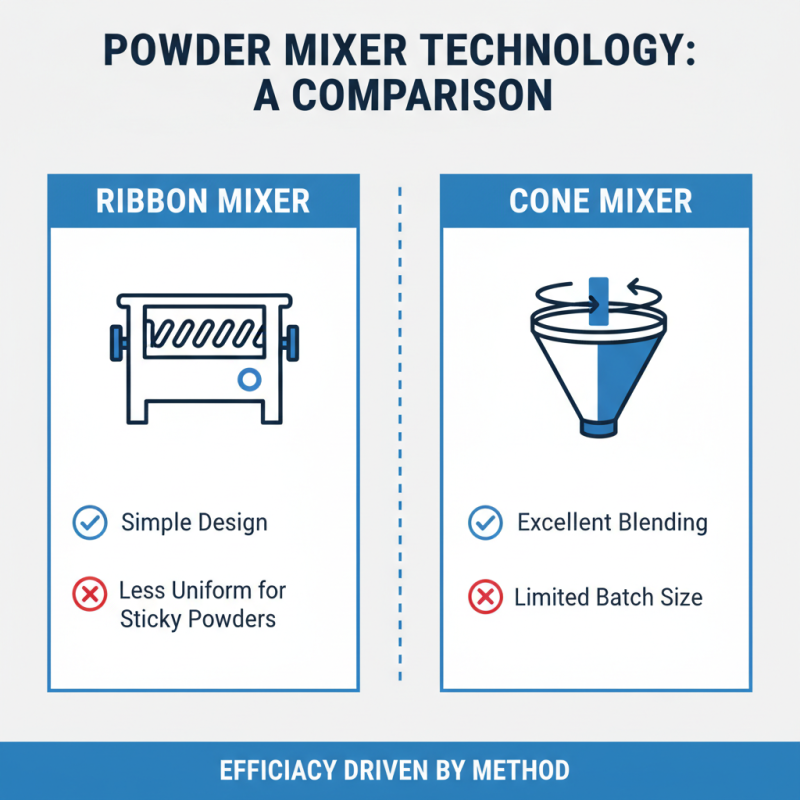

Comparative Analysis of Powder Mixer Technologies: Impact on Blending Efficacy

When selecting powder mixers, the technology plays a crucial role in blending efficacy. Different mixing methods yield varying outcomes, affecting the final quality of the product. For instance, a ribbon mixer offers a straightforward design but may not achieve uniformity with sticky powders. In contrast, a cone mixer excels at blending but can be limited by its batch size.

Understanding these distinctions is essential for industries relying on consistent results. The particle size and shape influence how powders interact during mixing. A high-shear mixer can reduce particle segregation but often requires more energy. Engineers sometimes overlook these factors, leading to inefficient operations.

The choice of mixer directly impacts efficiency and product quality. A V-blender can handle bulk powders well but may struggle with fine particles. Observing these limitations helps refine processes. Experimenting with different technologies can uncover unique insights. Continuous evaluation fosters improvements and might reveal unexpected challenges.

Industry Trends in Powder Mixing: Innovations and Future Directions

The powder mixing industry is evolving rapidly. Innovations are reshaping how powders blend. Advanced mixing technologies improve efficiency and consistency. New methods focus on reducing mixing times. This development minimizes variations in final products. However, challenges remain. Not all mixtures achieve the desired homogeneity.

Emerging trends in automation are evident. Automated systems enhance precision in the mixing process. Real-time monitoring of mixtures ensures quality control. Data analytics assist in adjusting parameters on the fly. These advancements offer advantages but also raise questions. Increased reliance on technology may reduce human oversight.

Sustainability is another significant trend. Eco-friendly materials and energy-efficient machines are gaining traction. Companies aim to minimize waste and reduce environmental impact. Yet, implementing these solutions can be costly. The industry must find a balance between innovation and feasibility. Blending optimal results with environmental responsibility is a complex endeavor.

Related Posts

-

Top Innovations in Best Powder Mixture Machines: Real-World Applications and Success Stories

-

How to Choose the Best Mixing Powder Machine for Your Needs?

-

Ultimate Guide to Choosing the Best Powder Mixers for Your Business Needs

-

Solutions for Efficient Production with Mixing Powder Machines

-

Exploring Unique Options for Mesin Mixer Powder in Industrial Applications

-

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?