Blog

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?

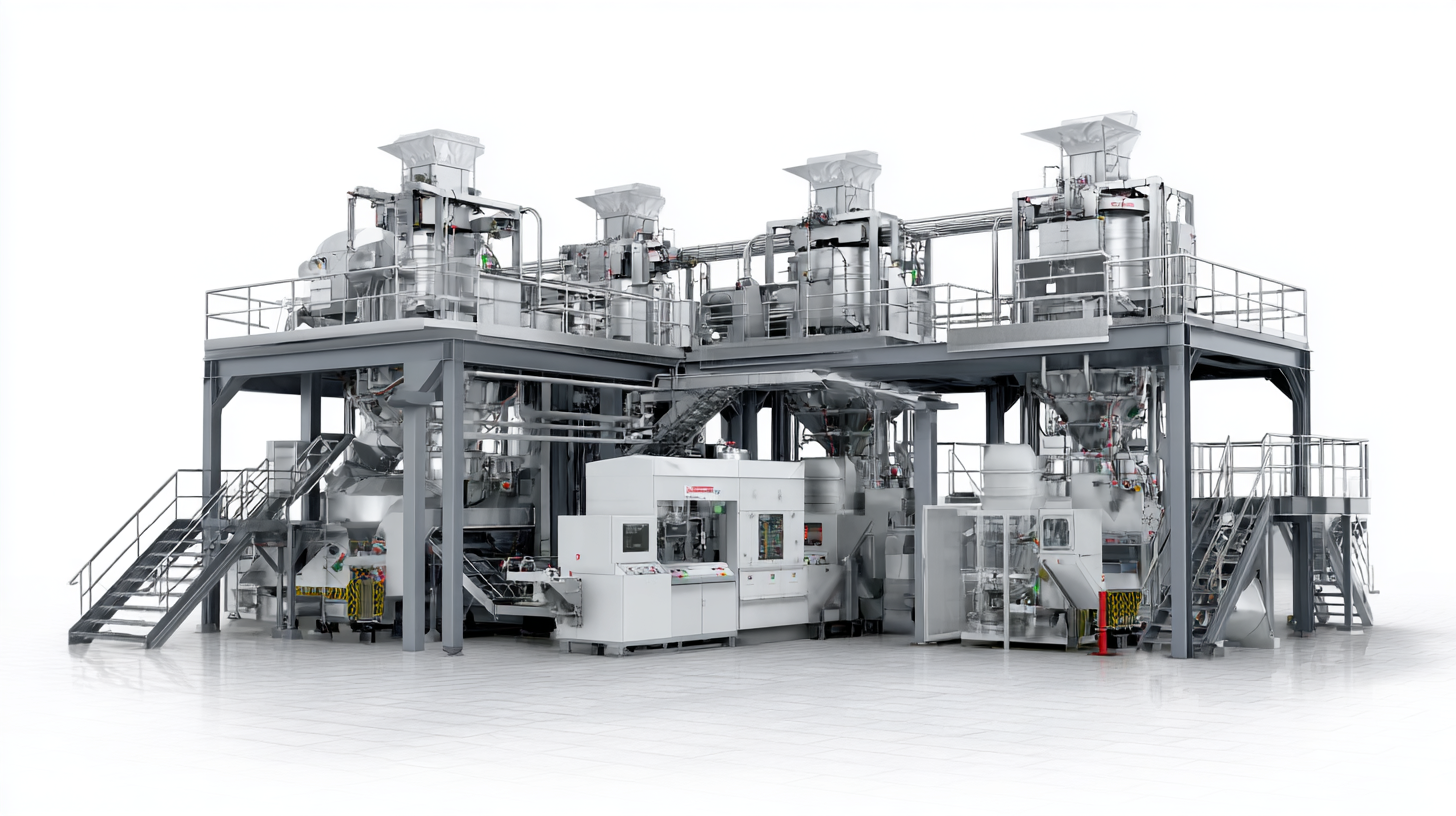

In the rapidly evolving landscape of material processing, the introduction of advanced technologies has significantly enhanced efficiency and precision. One such innovation is the Powder Mixture Machine, a pivotal device that streamlines the blending of powdered materials across various industries, including pharmaceuticals, food processing, and chemical manufacturing. According to a report by MarketsandMarkets, the global market for powder processing equipment is projected to reach $7.9 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.1%. These machines not only optimize the mixing process but also improve the consistency and quality of the final product, ensuring compliance with stringent industry standards. As the demand for high-quality powdered products continues to rise, the Powder Mixture Machine stands out as a revolutionary tool that transforms traditional material processing methods, setting new benchmarks for productivity and innovation.

Understanding the Basics: What Is a Powder Mixture Machine?

A powder mixture machine is an essential tool in various industries, primarily used to blend solid particles efficiently. At its core, this machine combines multiple powdered ingredients to achieve a homogenous mixture, which is critical in fields such as pharmaceuticals, food processing, and chemicals. According to a report by MarketsandMarkets, the global powder mixing equipment market is expected to reach USD 8.19 billion by 2025, growing at a CAGR of 5.9% from 2020. This growth signifies the increasing reliance on high-quality blending processes across multiple sectors.

The mechanism behind a powder mixture machine typically involves various mixing techniques, such as tumble blending, ribbon blending, and paddle mixing. Each type offers unique advantages depending on the properties of the materials involved. For instance, in the pharmaceutical sector, achieving a uniform powder blend is crucial for ensuring consistent drug dosage. A report from Research and Markets highlights that the pharmaceutical industry alone accounts for a significant share of the powder mixing equipment demand, driven by stringent regulatory requirements for product quality and efficacy. This essential machine not only enhances operational efficiency but also provides a competitive edge, enabling businesses to innovate and maintain high standards in material processing.

Key Features and Innovations in Modern Powder Mixture Machines

Modern powder mixture machines are at the forefront of material processing innovation, featuring advanced technologies that significantly enhance their efficiency and effectiveness. One key feature is the integration of precise weighing systems, which ensure accurate ingredient proportions. This capability is crucial in industries such as pharmaceuticals and food processing, where even minor discrepancies can lead to drastically different outcomes. Additionally, the use of advanced mixing blades and agitation mechanisms allows for a homogenous mix, reducing the risk of clumping and ensuring uniform quality in the final product.

Another notable innovation is the incorporation of smart technology within these machines. Many modern powder mixture machines now operate with sophisticated software that monitors the mixing process in real-time. This technology enables operators to adjust parameters on the fly, optimizing the mixing cycle based on material characteristics. Furthermore, automated cleaning systems have been developed, reducing downtime and enhancing productivity by allowing for quick transitions between different product types. Overall, these key features not only improve the mixing process but also contribute to the versatility and adaptability of powder mixture machines in a rapidly evolving material processing landscape.

Powder Mixture Machine Innovations and Features

How Powder Mixture Machines Enhance Efficiency in Material Processing

Powder mixture machines have become indispensable in modern material processing, significantly enhancing operational efficiency. These machines are designed to provide uniform blending of powders, ensuring that the final product meets specific quality standards. The precision with which these machines operate minimizes the time spent on mixing and reduces the risk of inconsistency, which can be detrimental in industries ranging from pharmaceuticals to food production.

One of the most remarkable advantages of powder mixture machines is their ability to automate the mixing process. By integrating advanced technology, such as programmable controls and sensors, these machines can optimize blending times and track the performance of the mixture in real-time. This not only streamlines operations but also allows manufacturers to maintain high levels of productivity while minimizing labor costs. As a result, businesses can focus their resources on other essential aspects of production, ultimately leading to an increase in profit margins and a stronger competitive edge in the marketplace.

Common Applications of Powder Mixture Machines Across Industries

Powder mixture machines are crucial in a variety of industries, enhancing efficiency and precision in material processing. These machines play a significant role in sectors like food production, pharmaceuticals, and metal additive manufacturing. For instance, the adoption of Laser Powder Bed Fusion (LPBF) in additive manufacturing has transformed how parts are produced, enabling complex geometries and lighter components that are essential for sectors such as aerospace and automotive. Reports indicate that the market for additive manufacturing technologies is expected to grow significantly, reaching an estimated value of $41 billion by 2025, spotlighting the importance of powder mixtures in achieving desired material properties and ensuring production quality.

In the food industry, the utilization of machine learning to analyze powder flowability is setting new standards in efficient manufacturing practices. Recent analyses revealed that the particle-size distribution in powder mixtures directly impacts flow characteristics, thereby influencing the consistency and quality of food products. Furthermore, powder mixture machines are being integrated with in-situ sensing and process monitoring technologies, providing real-time data to enhance machine uptime and reliability. This approach not only meets quality assurance standards but also minimizes production downtime, making powder mixture machines indispensable across various industrial applications.

Tips for Choosing the Right Powder Mixture Machine for Your Needs

When selecting the right powder mixture machine for your needs, it's essential to consider several key factors. First and foremost, evaluate the specific materials you intend to mix. Different powders have unique properties, such as density, particle size, and flow characteristics, which can greatly affect the mixing process. A machine that excels in blending fine powders might not be suitable for coarser materials, so understanding your material’s behavior is vital for optimal results.

Another crucial aspect is the machine’s capacity and efficiency. Depending on your production requirements, you’ll need a mixer that can handle the volume of materials you anticipate working with. Additionally, look for machines with adjustable mixing speeds and times to accommodate the varying consistency needed for different applications. It's also beneficial to consider the machine's ease of cleaning and maintenance, as this can save significant time and resources in a manufacturing environment. By carefully assessing these factors, you can choose a powder mixture machine that best aligns with your operational goals and improves your material processing effectiveness.

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?

| Feature | Description | Benefits |

|---|---|---|

| Mixing Capability | Able to blend various powdered materials uniformly. | Improves consistency in final product quality. |

| Batch Size | Available in various sizes to accommodate different production needs. | Flexibility for small to large-scale operations. |

| Ease of Cleaning | Designed for quick disassembly and cleaning. | Reduces downtime between batches and ensures hygiene. |

| Automation | Equipped with automated controls for precise mixing. | Enhances productivity and reduces labor costs. |

| Material Compatibility | Suitable for mixing a wide range of powders, including chemicals and food products. | Versatile usage in different industries. |

Related Posts

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing

-

Exploring Unique Options for Mesin Mixer Powder in Industrial Applications

-

How the Best Powder Pulverizer Transforms Food Processing: Industry Case Studies and Insights

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

Top Innovations in Best Powder Mixture Machines: Real-World Applications and Success Stories

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs