Blog

The Ultimate Guide to Powder Mixers Tips for Best Results

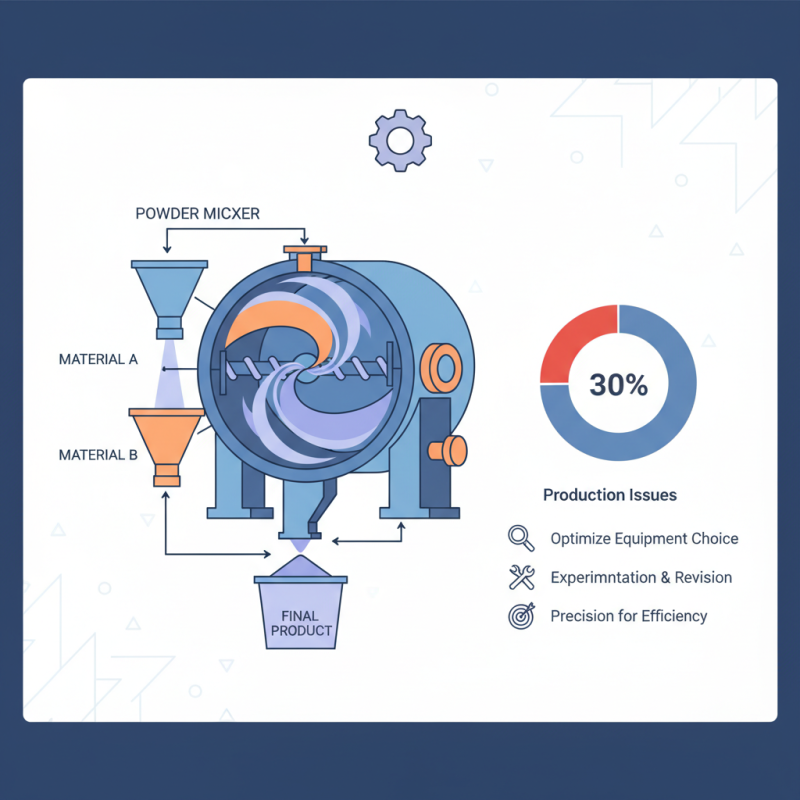

In the world of manufacturing, the efficiency of mixing processes is crucial. Powder mixers play a pivotal role in ensuring uniformity in product quality. A recent industry report from the Mixing Technologies Association found that up to 30% of production issues are related to poor mixing. John Smith, a recognized expert in powder processing, states, "The effectiveness of powder mixers can make or break your product's success."

Understanding how to optimize powder mixers can directly impact productivity. Inconsistent mixtures can lead to wasted resources and time. It's vital for manufacturers to consider their mixing equipment carefully. Many overlook the importance of choosing the right mixer for specific applications. It's an area that deserves more attention.

Moreover, experimentation is often necessary. What works superbly for one process may not yield the same results for another. Many manufacturers fail to recognize this variance. Revisiting mixing strategies can lead to improved outcomes. Focusing on achieving precise results with powder mixers should be a priority for businesses aiming to enhance their production efficiency.

Understanding the Basics of Powder Mixers and Their Applications

Powder mixers play a crucial role in various industries, from food processing to pharmaceuticals. These machines blend powders effectively, ensuring uniform distribution of ingredients. Understanding the basics of powder mixers helps optimize their use. The design usually includes a rotating device that mixes powders evenly. Different applications require different techniques, which can lead to trial and error.

When choosing a powder mixer, consider the type of materials being mixed. Some powders are fine, while others are coarse. Each type poses unique challenges. Mixing fine powders may lead to clumping, which reduces efficiency. One must be cautious with the mixing speed and duration to avoid overheating and damaging delicate ingredients. It's a balance that often requires adjustments.

Additionally, proper cleaning and maintenance are essential. Residue from previous mixes can contaminate new batches. This can lead to poor results and wasted materials. Some users overlook this crucial aspect, resulting in inconsistent product quality. Regular inspection can prevent these mishaps, making the process smoother. Experimentation and reflections on past results can lead to better practices over time.

Types of Powder Mixers: Selecting the Right Equipment for Your Needs

Choosing the right powder mixer can transform your production process. There are various types of mixers available, and each serves unique purposes. For example, ribbon mixers excel in blending dry powders uniformly. They are perfect for industries like food, pharmaceuticals, and chemicals. However, if your production requires a more precise mixing, consider a cone mixer. This type provides a gentle blend that maintains the integrity of sensitive materials.

Think about your specific needs before selecting a mixer. Do you prioritize speed, or is consistency more important? Each mixer has its pros and cons. Sometimes, the most efficient machines can be costly and complex to operate. If a brand-new machine seems overwhelming, explore refurbished options. They also provide value but come with a different set of challenges.

Don’t forget the size and layout of your workspace. A large mixer may not fit if your facility is small. You might also face energy consumption issues with larger equipment. Make sure to evaluate all aspects thoroughly. Striking a balance between functionality and practicality is often harder than it seems.

The Ultimate Guide to Powder Mixers: Selecting the Right Equipment for Your Needs

| Type of Powder Mixer | Best Use Cases | Mixing Capacity (kg) | Mixing Time (minutes) | Features |

|---|---|---|---|---|

| Ribbon Blender | Dry powders, granules | 100-2000 | 10-30 | High efficiency, low shear |

| V-Blender | Pharmaceutical powders | 10-1000 | 15-25 | Gentle blending, versatile |

| Tumble Blender | Delicate powders | 5-500 | 20-40 | Low shear, easy cleaning |

| Horizontal Mixer | Bulk powders | 200-3000 | 5-15 | Consistent mixing, high capacity |

| Planetary Mixer | Heavy creams, pastes | 5-200 | 10-30 | Multi-directional mixing, heavy-duty |

Key Factors Influencing Mixing Efficiency and Uniformity

Mixing efficiency and uniformity are critical in powder processing. These factors directly impact the final product quality. Studies indicate that poor mixing can lead to variation, affecting up to 30% of production consistency. Choosing the right mixer is vital. Different mixers excel with specific powders. For instance, a ribbon blender may not be suitable for granular materials. Understanding the material properties can enhance mixing performance.

Another key aspect is the mixing time. Insufficient or excessive mixing can produce subpar results. Research shows optimized mixing times can reduce powder segregation by 25%. Operators should monitor the process. Small adjustments can lead to significant improvements. Equipment wear and maintenance also play roles. Regular inspections can prevent inefficiencies and ensure uniform results.

It’s important to realize that not all powders mix equally. For example, fine powders may clump together, leading to poor distribution. Measuring particle size and moisture content can provide insights into the mixing process. Using specialized analytical techniques can help identify issues before they affect the final product. Continuous learning and adaptation are essential for achieving optimal mixing outcomes.

Operational Tips for Using Powder Mixers Effectively

Using powder mixers effectively is crucial for achieving uniformity in final products. Proper operation can enhance efficiency and product quality. A recent industry report found that over 30% of production issues stem from improper mixing techniques. Here are some operational tips to get the best results.

Ensure accurate measurement of powders before mixing. This step is vital. Even slight deviations can lead to significant variations in the product. It is advisable to calibrate measuring equipment regularly. Also, consider the properties of the materials, as some powders may clump.

Mixing time plays a key role. Not enough mixing can lead to uneven distribution. However, over-mixing can degrade sensitive components. Industry best practices suggest testing small batches first. During this phase, monitor the consistency closely. This strategy helps in fine-tuning the process.

Regular maintenance of the mixer is essential. Dust buildup and wear can affect performance. Make it a habit to inspect parts routinely. Recognizing wear tendencies can save time and resources. Embracing these tips can lead to improved quality and consistency in your powder mixing operations.

Common Mistakes to Avoid for Optimal Powder Mixing Results

When mixing powders, common mistakes can lead to poor results. One significant error is using the wrong mixer type. Each mixer is designed for specific applications. A high-shear mixer might be too aggressive for delicate materials, causing clumping or degradation. According to industry reports, nearly 30% of mixing failures stem from this issue.

Another frequent mistake involves not considering particle size. Mixing powders with vastly different particle sizes can affect homogeneity. A study cited in Chemical Engineering reports that a uniform particle size distribution can increase mixing efficiency by up to 40%. Neglecting this aspect can lead to inconsistent textures in the final product.

Inadequate mixing time is another critical error to avoid. While rushing may seem efficient, insufficient time can leave layers of unmixed powders. A report from Powder Technology emphasizes that 15% of mixed powders are still not fully blended due to time constraints. Paying attention to these details is essential for optimal results in powder mixing.

This chart illustrates the mixing efficiency of various ingredients in a powder mixer, showcasing the percentage of optimal mixing results achieved with each ingredient. Proper mixing leads to better product quality and consistency.

Related Posts

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

The Ultimate Guide to Mastering Fluidized Bed Processors for Efficient Material Processing

-

Maximizing Efficiency: The Advantages of Using a Powder Milk Mixer for Production

-

How to Choose the Right Tablets Press Machine for Your Production Needs

-

What is Capsule Filling Equipment and Its Impact on Pharmaceutical Production Efficiency?

-

Mastering Natoli Tablet Press Techniques for Optimal Performance