Blog

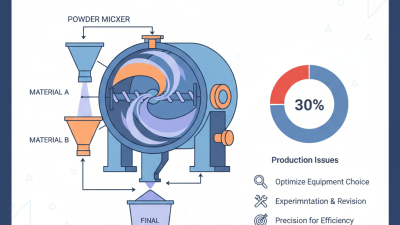

What is a Powder Mixer and How Does it Work?

In the world of manufacturing, Powder Mixers play a crucial role. These machines blend dry ingredients uniformly, ensuring consistency in various products. According to a recent industry report by Smith Research, the Powder Mixers market is expected to grow by 6% annually through 2028. This growth highlights their importance in food, pharmaceuticals, and chemicals.

Renowned industry expert Dr. Emily Thompson states, “The efficiency of Powder Mixers can directly impact product quality.” Her insight underscores the necessity for manufacturers to invest in high-quality mixing equipment. Despite advancements in technology, some mixers struggle with achieving the desired level of homogeneity.

Moreover, the choice of mixing method can affect the final product. The challenge lies in selecting the right type of Powder Mixer for specific applications. As the demand for specialized mixtures increases, manufacturers must reassess their practices. Balancing cost and efficiency remains a common concern. This pursuit for optimal performance should drive innovation in the Powder Mixers sector.

What is a Powder Mixer?

A powder mixer is a machine designed to blend different powdered materials efficiently. These machines are crucial in industries like food, pharmaceuticals, and chemicals. They ensure uniformity in products by mixing ingredients thoroughly to achieve the desired consistency.

The operation of a powder mixer often involves the use of blades or paddles that rotate within a chamber. This motion promotes the even distribution of particles. Some mixers utilize gravity, while others rely on mechanical forces. During this process, it’s vital to consider factors like the flow characteristics of the powders. Mixing can sometimes lead to segregation if not done carefully.

**Tip:** Always test small batches first to identify mixing issues. Monitor the speed and duration, as these can greatly affect consistency.

Different types of powder mixers exist, each with its own advantages. For instance, tumble mixers are simple but can be less efficient. Use them for free-flowing powders, but be mindful of their limitations.

**Tip:** Consider the material properties of the powders. Mixing properties vary widely among different powders. Not all powders will mix on the first go; some experimentation may be necessary.

Powder Mixer Performance Analysis

Types of Powder Mixers and Their Uses

Powder mixers come in various types, each designed for specific applications. A common type is the tumble mixer. It uses gravity to ensure even distribution of powders. The mixer has a rotating drum that tumbles the powder. This method is simple and widely used in many industries. However, sometimes it may not achieve the desired homogeneity, especially with very fine particles.

Another type is the ribbon blender. This mixer features a set of helical ribbons that move powders in both axial and radial directions. This action helps to efficiently blend different materials. However, it might require longer mixing times for certain formulations. It’s crucial to monitor the process closely to avoid over-mixing, which can lead to clumping.

Lastly, we have the high-shear mixer. This machine applies a combination of mechanical and hydraulic forces to mix powders. High-shear mixers are ideal for creating homogeneous mixtures, especially with viscous materials. But, they can be sensitive to heat generation. Proper temperature control is essential to prevent degradation of sensitive ingredients. Each type has its strengths and weaknesses, and choosing the right one depends on the specific requirements of the mixing process.

Principles of Powder Mixing: How It Works

Powder mixing is essential in various industries, including pharmaceuticals, food, and chemicals. It involves combining different powdered materials to create a uniform mixture. The principles of powder mixing focus on the interaction between particles. Understanding these principles is critical for achieving a consistent product.

The efficiency of powder mixing relies on factors like particle size, shape, and density. Studies indicate that smaller particles tend to mix more uniformly due to their higher surface area. A report from the International Journal of Pharmaceutics highlights that achieving a homogenous blend can be challenging when dealing with powders of varying sizes. The complexities of segregation can lead to inconsistent product quality.

Another key principle is the mixing time. Research shows that longer mixing times do not always guarantee better homogeneity. Sometimes, overmixing can result in the degradation of sensitive components. Finding the right balance is crucial. Industry data suggests that optimal mixing times typically range from 5 to 15 minutes, depending on the materials involved. This evidence showcases the importance of tailored mixing protocols in industrial applications.

Applications of Powder Mixers in Various Industries

Powder mixers are essential in many industries. They facilitate the blending of powdered materials to achieve uniformity. In the food industry, these mixers help combine spices and ingredients efficiently. This ensures that every batch has the same flavor and texture. The right mix is vital for consistency.

In pharmaceuticals, powder mixers play a significant role. They ensure that active ingredients are evenly distributed throughout the formulations. This is critical for dosage accuracy. An uneven mixture could lead to ineffective or even harmful products. Manufacturers must pay close attention to the mixing process.

In the construction industry, powder mixers are used for blending materials like cement and additives. A good mix determines the strength of the final product. However, not every approach yields perfect results. Sometimes, operators face challenges like clumping. Experimentation is often needed to find optimal settings. Mistakes can be costly, highlighting the importance of precision.

What is a Powder Mixer and How Does it Work? - Applications of Powder Mixers in Various Industries

| Industry | Application | Type of Powder Mixer | Mixing Time (minutes) |

|---|---|---|---|

| Pharmaceutical | Active Ingredient Mixing | V-Blender | 10 |

| Food Industry | Spice Blending | Ribbon Mixer | 15 |

| Cosmetics | Powdered Makeup Production | Planetary Mixer | 12 |

| Chemical | Powder Coatings | Double Cone Mixer | 8 |

| Construction | Cement Powder Mixing | Screw Mixer | 20 |

Key Factors Influencing Powder Mixer Performance

When evaluating the performance of powder mixers, several key factors come into play. The size of the mixing chamber is crucial. A chamber too small may lead to inefficient mixing. Conversely, an excessively large chamber can cause uneven distribution of materials. The geometry and design of the blades also significantly impact mixing outcomes. Blade shape and arrangement can enhance or hinder flow patterns. This influences how well ingredients combine.

Another fundamental aspect is the properties of the powders themselves. For instance, particle size can affect how quickly they blend. Finer powders may mix more easily than larger particles. Moisture content is another variable. Excess moisture can cause clumping, while insufficient moisture might lead to dust. It's essential to tweak these factors based on the specific materials being mixed.

Temperature during mixing can’t be overlooked either. Some powders respond differently under varying heat conditions. Adjusting the temperature can enhance or deteriorate mixing efficiency. These factors lead to reflections on how to optimize your mixing processes. Sometimes what works for one batch might not work for another, revealing the need for continuous improvement.

Related Posts

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing

-

Why Investing in a Mesin Mixer Powder is Essential for Your Production Efficiency

-

Top 10 Benefits of Using Mixer Powder for Your Cooking Needs

-

The Ultimate Guide to Powder Mixers Tips for Best Results

-

2026 Top Powder Mixture Machine Innovations and Their Impact on Industries?