Blog

Why Investing in a Mesin Mixer Powder is Essential for Your Production Efficiency

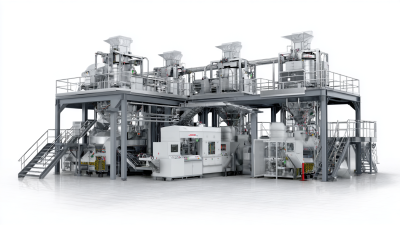

In today's fast-paced manufacturing landscape, the pursuit of efficiency and productivity has become paramount. A key player in this quest is the Mesin Mixer Powder, a crucial piece of equipment that significantly enhances the mixing and blending processes in various industries, including pharmaceuticals, food, and plastics. According to a report by Grand View Research, the global mixer market is expected to reach $6.5 billion by 2025, highlighting a compound annual growth rate of 4.2%. This trend underscores the importance of investing in advanced mixing technologies to stay competitive.

Industry expert Dr. Sarah Thompson, a leading authority on powder processing, emphasizes, "The adoption of high-quality mixing equipment such as the Mesin Mixer Powder can reduce production time and waste, ultimately leading to improved profitability." By integrating this advanced technology into production lines, manufacturers can achieve uniformity and consistency in their products, resulting in higher customer satisfaction and reduced rework costs. As we delve deeper into the reasons why investing in a Mesin Mixer Powder is indispensable for enhancing production efficiency, it becomes clear that this decision is not just beneficial, but essential for future growth and competitiveness in the market.

Benefits of Using a Mesin Mixer Powder in Production Processes

Investing in a mesin mixer powder can significantly enhance production efficiency across various industries. One of the primary benefits is the uniformity it brings to the mixing process. Achieving a consistent blend of materials is crucial in manufacturing, as it directly impacts product quality. Whether it's for pharmaceuticals, food production, or chemicals, a mesin mixer ensures that each batch meets the required specifications, reducing waste and minimizing errors.

Additionally, mesin mixers can speed up production times. Traditional mixing methods can be labor-intensive and time-consuming, often leading to bottlenecks in the production line. Modern mesin mixers are designed to handle large volumes of materials simultaneously, which not only accelerates the mixing process but also frees up labor for other tasks. This efficiency translates into higher output and reduced operational costs, ultimately enhancing profitability for the business. By streamlining production processes, companies can respond more swiftly to market demands and improve their overall competitiveness.

Impact of Mesin Mixer Powder on Production Efficiency

Key Factors to Consider When Choosing a Mesin Mixer Powder

When selecting a Mesin Mixer Powder, it is crucial to consider several key factors that can significantly impact your production efficiency. First and foremost, the capacity of the mixer should align with your production demands. A mixer that is too small may not meet your needs, leading to delays and inefficiencies. Conversely, an oversized mixer can lead to increased energy costs and unnecessary space consumption.

Assessing your operational requirements will help you choose the right size for optimal performance.

When selecting a Mesin Mixer Powder, it is crucial to consider several key factors that can significantly impact your production efficiency. First and foremost, the capacity of the mixer should align with your production demands. A mixer that is too small may not meet your needs, leading to delays and inefficiencies. Conversely, an oversized mixer can lead to increased energy costs and unnecessary space consumption.

Assessing your operational requirements will help you choose the right size for optimal performance.

Another important factor is the material construction of the mixer. High-quality materials not only enhance durability but also ensure effective mixing. Stainless steel, for example, is resistant to corrosion and easy to clean, which is vital in maintaining hygiene in production processes. Additionally, examining the mixing technology and features such as automatic controls or advanced mixing mechanisms can improve consistency and reduce processing time. By focusing on these elements, you can select a Mesin Mixer Powder that enhances productivity and meets your quality standards.

How Mesin Mixer Powder Enhances Product Consistency and Quality

Investing in a Mesin Mixer Powder significantly enhances product consistency and quality, a crucial factor for any production environment. This advanced equipment ensures uniform mixing of ingredients, which minimizes variability in the final product. By thoroughly blending powders, the Mesin Mixer Powder eliminates clumps and uneven distribution, resulting in a homogeneous mixture. Such consistency is vital for industries ranging from pharmaceuticals to food production, where precise formulations are necessary to meet regulatory standards and customer expectations.

Moreover, the Mesin Mixer Powder contributes to improved quality control throughout the production process. With its ability to mix ingredients uniformly, manufacturers can achieve better texture, flavor, and overall product performance. This heightened level of quality not only boosts consumer satisfaction but also strengthens brand reputation. Furthermore, consistent quality reduces the likelihood of production errors and waste, ultimately leading to cost savings and increased efficiency. By prioritizing product consistency through the use of Mesin Mixer Powder, businesses can position themselves as leaders in their respective markets.

The Impact of Mesin Mixer Powder on Production Time and Cost Efficiency

Investing in a mesin mixer powder can significantly enhance production time and cost efficiency. According to a report by the American Society of Mechanical Engineers, utilizing advanced mixing equipment can reduce mixing time by as much as 40%. This reduction allows manufacturers to meet tight deadlines and increase output, vital in today’s fast-paced market. Enhanced mixing consistency further minimizes the chances of product defects, ensuring that production runs smoothly and reducing the need for costly reworks.

Moreover, the adoption of mesin mixer powder contributes to cost efficiency through energy savings. According to a study by Industrial Mixers International, modern mixing machines are designed to consume up to 30% less energy compared to older models. This reduction in energy usage not only lowers operational costs but also aligns with sustainable practices that more companies are prioritizing. By optimizing both time and resources, companies can effectively improve their bottom line while maintaining high-quality production standards.

Innovative Features of Modern Mesin Mixer Powder Technology

Modern Mesin Mixer Powder technology has revolutionized the way industries handle powder mixing processes. One of the most significant innovations is the integration of advanced automation features, allowing for precise control and monitoring of mixing parameters. This capability not only enhances consistency in product quality but also reduces the chances of human error during operation. With real-time data analytics, manufacturers can now optimize mixing times and ingredient ratios, leading to improved overall efficiency and reduced waste.

Another remarkable feature is the design of high-performance mixing blades that ensure a thorough and uniform blend of powders. These blades can be adjusted for different material types, catering to diverse production needs across various sectors. Additionally, many modern machines include touchscreen interfaces, providing operators with user-friendly controls and instant access to operational metrics. This ease of use encourages quick adjustments and minimizes downtime, which is essential for maintaining high production rates and meeting increasing market demands.

Why Investing in a Mesin Mixer Powder is Essential for Your Production Efficiency - Innovative Features of Modern Mesin Mixer Powder Technology

| Feature | Description | Impact on Production | Efficiency Improvement (%) |

|---|---|---|---|

| High Mixing Speed | Increased RPM allows for faster mixing times. | Reduces overall production time. | 30% |

| Automated Mixing Control | Precision controls for consistent results. | Improves product quality and reduces waste. | 25% |

| Energy Efficiency | Design minimizes energy consumption. | Lower operating costs. | 20% |

| Versatile Mixing Capability | Handles various powder types and sizes efficiently. | Expands product line offerings. | 15% |

| Easy Maintenance | Simplified access to components for cleaning. | Less downtime for maintenance. | 10% |

Related Posts

-

Solutions for Efficient Production with Mixing Powder Machines

-

Exploring Unique Options for Mesin Mixer Powder in Industrial Applications

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

Top Innovations in Best Powder Mixture Machines: Real-World Applications and Success Stories

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing

-

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?