Blog

Why Invest in a Syringe Assembly Machine for Your Manufacturing Needs

In recent years, the demand for medical devices, particularly syringes, has seen significant growth due to advancements in healthcare and an increase in vaccination initiatives worldwide. As a result, the efficient production of syringe assemblies has become paramount for manufacturing entities aiming to maintain competitiveness and meet market demands. Investing in a Syringe Assembly Machine is not just a strategic move, but a vital necessity for manufacturers looking to enhance their production capabilities and ensure consistent quality in their output.

A Syringe Assembly Machine automates the intricate processes involved in syringe production, streamlining operations while reducing labor costs and minimizing human error. This technological innovation enhances not only the speed of manufacturing but also the precision required in medical applications, thereby meeting stringent regulatory standards. Furthermore, the incorporation of such machinery allows manufacturers to scale their operations effectively, catering to increasing consumer needs without compromising quality. In this article, we explore the critical factors that underline the importance of investing in a Syringe Assembly Machine for your manufacturing needs and how it can propel your business towards success in a rapidly evolving market.

Benefits of Automating Syringe Assembly Processes in Manufacturing

The automation of syringe assembly processes presents a transformative opportunity for manufacturers in the medical device sector. A recent report from the International Federation of Robotics highlights that the use of industrial robots in manufacturing has increased by over 20% in the past five years, particularly in the medical field. This shift towards automation not only enhances efficiency but also improves precision, crucial for maintaining the high standards required in syringe production. Automated systems can assemble syringes at a much faster rate than manual labor, with speeds reported to reach up to 300 units per minute, significantly reducing production times and increasing output.

Moreover, investing in a syringe assembly machine can greatly minimize human errors, which are a critical concern in medical manufacturing. According to a study conducted by the Institute of Manufacturing, the implementation of automated assembly has led to a 30% reduction in defects. This means that manufacturers can achieve higher quality control, ensuring that every syringe meets the stringent regulatory standards. As the demand for syringes has surged—spurred on by recent global health events—automating the assembly process becomes not just advantageous but essential for meeting production targets and maintaining competitiveness in the market.

Market Trends in Syringe Production: Growth and Demand Analysis

The global syringe production market is witnessing significant growth, driven by an increasing demand for vaccinations, medical procedures, and chronic disease management. The rise in public health initiatives and the urgent need for efficient medical supplies have propelled syringe manufacturing to the forefront. With advancements in healthcare technology and heightened awareness of hygiene practices, the importance of high-quality syringe production has become even more pronounced.

Market analysis indicates a sustained upward trend in syringe demand, particularly with the growing emphasis on preventive healthcare. Governments and health organizations are investing in vaccination programs, especially in the wake of recent global health challenges. This surge not only signifies a need for more syringes but also underscores the necessity for modernizing manufacturing processes to meet these demands.

The implementation of advanced syringe assembly machines can enhance production efficiency, reduce waste, and guarantee the precision required for safe and effective medical applications. As manufacturers respond to these market trends, investing in state-of-the-art machinery emerges as a critical strategy for success in this expanding sector.

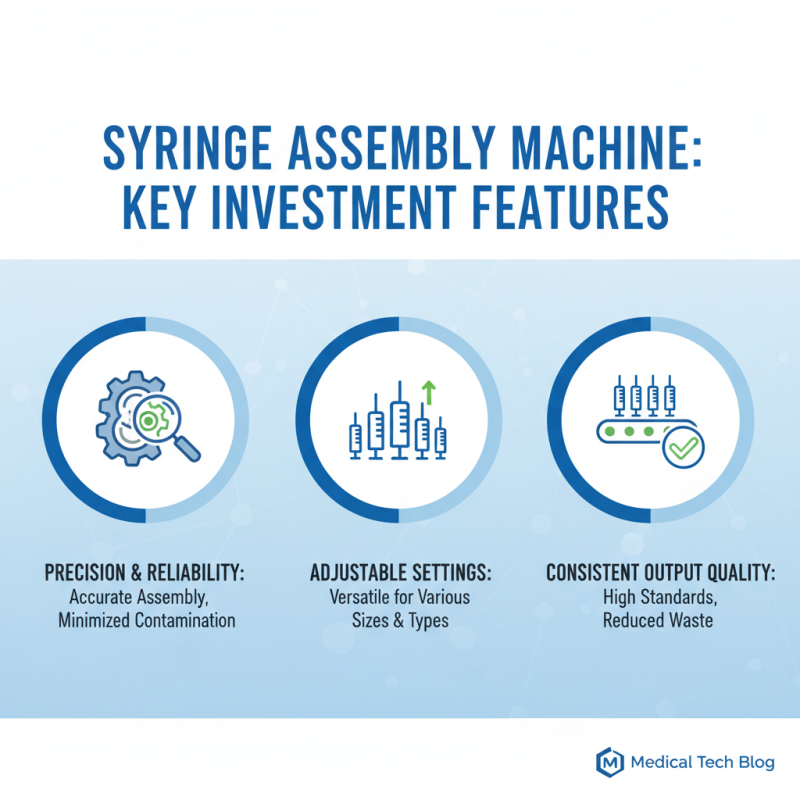

Key Features to Look for in Syringe Assembly Machines

When considering the investment in a syringe assembly machine for manufacturing needs, it is crucial to focus on specific key features that can enhance efficiency and product quality. First, precision and reliability are paramount; a machine should be able to assemble syringes with a high degree of accuracy to ensure proper dosages and minimize the risk of contamination. Look for machines that offer adjustable settings for different syringe sizes and types, allowing for versatile manufacturing options while maintaining a consistent output quality.

Another significant feature to consider is automation capabilities. Advanced syringe assembly machines should integrate automated processes that reduce manual labor and improve production speed. Automated systems can facilitate the loading, assembly, and packaging of syringes, resulting in a more efficient production line. Additionally, user-friendly interfaces and real-time monitoring systems can allow operators to easily manage the machine's performance while ensuring top-notch operational standards. Such features not only streamline the manufacturing process but also help in maintaining compliance with industry regulations.

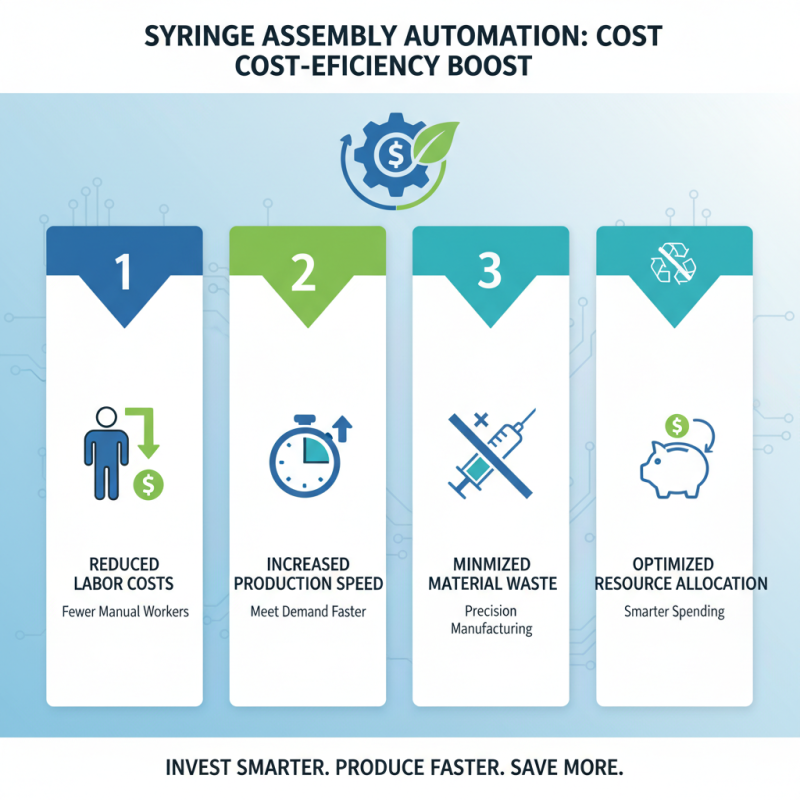

Cost-Efficiency and Return on Investment for Manufacturing Facilities

Investing in a syringe assembly machine can significantly enhance cost-efficiency for manufacturing facilities. Automation offered by these machines reduces the need for extensive manual labor, leading to lower operational costs. With increased production speeds, facilities can meet higher demand without the need to increase workforce size, ultimately saving on labor expenses. The precision of automated machinery also minimizes material wastage, further lowering manufacturing costs. By streamlining the assembly process, businesses can optimize their resource allocation, ensuring that funds are spent more effectively across production lines.

Moreover, the return on investment (ROI) from a syringe assembly machine can be profound. Facilities adopting such technology often experience faster product turnaround times, allowing them to respond swiftly to market demands. This agility not only enhances customer satisfaction but also boosts market competitiveness. As production efficiency improves, the incremental profits generated from swift turnover can quickly offset the initial investment costs. With the ongoing trend toward automation in the manufacturing sector, integrating a syringe assembly machine is a strategic move that aligns with long-term growth and profitability goals.

Regulatory Compliance and Quality Control in Syringe Production

In the highly regulated field of medical device manufacturing, compliance with stringent regulations is paramount. A syringe assembly machine is not merely a production tool; it plays a critical role in ensuring that every syringe produced meets the required standards set forth by regulatory bodies. These machines are designed to facilitate precision and consistency in the assembly process, which is essential for meeting quality control benchmarks. The integration of automated systems enhances the traceability of components, allowing manufacturers to maintain comprehensive records that demonstrate adherence to regulatory guidelines.

Moreover, the implementation of advanced syringe assembly machines can significantly improve the overall quality control in production. By utilizing cutting-edge technologies, manufacturers can identify potential defects in real-time, minimizing the risk of non-compliance and ensuring that only high-quality products reach the market. The ability to conduct thorough inspections and validations during the assembly process ensures that every syringe meets both safety and efficacy requirements, which is crucial for maintaining consumer trust. In a competitive marketplace, investing in these machines not only enhances regulatory compliance but also reinforces a commitment to quality that can distinguish a manufacturer within the industry.

Related Posts

-

7 Best Features of Syringe Assembly Machines for Optimal Production Efficiency

-

The Ultimate Guide to Choosing the Right Capsule Loader Machine for Your Business Needs

-

Top Capsules Filling Machines of 2025 for Efficient Pharmaceutical Production

-

The Evolution of Tableting Machines in Modern Pharmaceutical Manufacturing

-

Ultimate Guide to Selecting the Right Tablets Press Machine Tips for Success

-

What is Natoli Tablet Press and How Does It Improve Tablet Production