Blog

The Evolution of Tableting Machines in Modern Pharmaceutical Manufacturing

The evolution of Tableting Machines has dramatically transformed modern pharmaceutical manufacturing, enhancing efficiency, precision, and productivity in drug production. According to a report by Grand View Research, the global pharmaceutical manufacturing market was valued at approximately $1.2 trillion in 2021 and is anticipated to grow at a compound annual growth rate (CAGR) of over 7.5% from 2022 to 2030. This growth underscores the increasing demand for advanced technology in manufacturing processes, with tableting machines playing a pivotal role in streamlining operations and improving product quality. Innovations such as continuous manufacturing and the integration of artificial intelligence into tablet production have led to significant improvements in throughput and cost efficiency. As pharmaceutical companies strive to meet while also catering to the growing global consumer base, the advancements in tableting machinery become crucial in sustaining competitive advantage and ensuring the consistent delivery of safe, effective medications.

Understanding Tableting Machines: Key Components and Their Roles

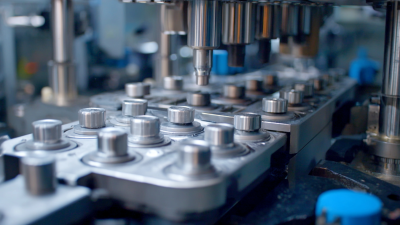

Tableting machines are essential in modern pharmaceutical manufacturing, playing a crucial role in transforming powdered ingredients into solid dosage forms. Understanding the key components of these machines is vital for grasping their functionality and efficiency. At the heart of a tableting machine lies the punch and die system. The punches compress the powder, while the dies shape it into tablets of specified dimensions. This process requires precision to ensure uniformity and quality in the final product.

Another significant component is the feed system, which ensures a consistent supply of powder to the punches. This system often includes an auger or a gravity feed mechanism that must be carefully calibrated to maintain proper flow rates and avoid product wastage. Additionally, the tablet compression force is adjustable, allowing manufacturers to optimize the hardness and dissolution characteristics of the tablets according to pharmaceutical standards. By understanding these components and their roles, manufacturers can enhance the efficiency, safety, and efficacy of the drug production process, thus adapting to the ever-evolving demands of the pharmaceutical industry.

The Evolution of Tableting Machines in Modern Pharmaceutical Manufacturing

This chart illustrates the advances in key components of tableting machines over the last two decades, highlighting their evolution in efficiency and technology.

The Advancements in Tableting Technology: From Manual to Automated Processes

The landscape of tableting technology has undergone remarkable transformations, transitioning from manual processes to highly automated systems. In the early stages of pharmaceutical manufacturing, tablet production was a labor-intensive endeavor, relying heavily on skilled operators to mix, compress, and package medications. These manual methods, while effective, were often time-consuming and prone to human error, leading to inconsistencies in dosage and product quality.

With the advent of modern automation, tableting machines have become increasingly sophisticated, offering enhanced precision and efficiency. Innovations such as Computer Numerical Control (CNC) technology and advanced monitoring systems allow for real-time adjustments during the manufacturing process. Automated tableting lines can achieve higher throughput with minimal intervention, significantly reducing production times. These advancements not only improve the accuracy of tablet formulations but also help ensure compliance with stringent regulatory standards, ultimately benefiting both manufacturers and consumers alike.

The Evolution of Tableting Machines in Modern Pharmaceutical Manufacturing

| Year | Technology Type | Key Features | Production Rate (Tablets/min) | Automation Level |

|---|---|---|---|---|

| 1950 | Manual Press | Hand-operated, low efficiency | 30 | None |

| 1970 | Semi-Automatic Press | Mechanical feed, increased speed | 100 | Partial |

| 1990 | Automatic Rotary Press | High speed, continuous operation | 500 | Full |

| 2010 | High-Speed Tableting Machine | Advanced controls, efficiency improvements | 1000 | Full |

| 2023 | Smart Tableting Systems | AI integration, real-time monitoring | 1500 | Full |

Enhancing Efficiency: How Modern Tableting Machines Improve Production Rates

In recent years, the pharmaceutical manufacturing landscape has been revolutionized by advancements in tableting technology. Modern tableting machines have significantly improved production rates by incorporating automation and advanced control systems. According to a report by the International Society for Pharmaceutical Engineering (ISPE), the implementation of automated tablet press systems can enhance production efficiency by up to 30%, allowing manufacturers to meet increasing market demands without compromising quality. These machines can operate at higher speeds, producing thousands of tablets per minute, which substantially reduces the time required for large-scale production.

Moreover, the integration of real-time monitoring systems within these modern machines ensures that the quality of the tablets meets regulatory standards. A study published in the Journal of Pharmaceutical Sciences highlighted that real-time process analytical technologies (PAT) can lead to a 25% increase in first-pass yield, minimising waste and rework. As manufacturers strive to optimize their operations, the evolutionary leap in tableting machines not only accelerates output but also enhances product consistency, ultimately driving profitability in a highly competitive market.

Quality Control in Tableting: Ensuring Consistency and Potency in Pharmaceuticals

In the modern pharmaceutical industry, the significance of quality control in tableting cannot be overstated. Effective quality control measures are essential to ensure the consistency and potency of pharmaceutical products, as variations in tablet production can lead to severe consequences for patient safety and efficacy. According to the International Society for Pharmaceutical Engineering (ISPE), approximately 70% of drug recalls are attributed to manufacturing defects, highlighting the critical need for robust quality control in the tableting process.

To guarantee that tablets meet the required standards, pharmaceutical manufacturers employ various techniques, including in-process testing and statistical quality control. Advanced tableting machines now incorporate technologies such as real-time monitoring and automated quality assurance systems, which allow for immediate detection of deviations in tablet weight, hardness, and dissolution rates. A report from the McKinsey Center for Advanced Analytics indicates that companies using these technologies can improve compliance rates by up to 30%, significantly reducing the risk of non-compliance issues and enhancing overall product quality. As the pharmaceutical landscape continues to evolve, the integration of high-quality control standards in tableting processes remains paramount for ensuring patient safety and therapeutic effectiveness.

Future Trends in Tableting Machines: Innovations Shaping the Pharmaceutical Industry

In the rapidly advancing pharmaceutical industry, innovations in tableting machines are pivotal in enhancing production efficiency and product quality. Future trends highlight the integration of smart technology in these machines, allowing for real-time monitoring and adjustments during the manufacturing process. This not only improves consistency in tablet production but also minimizes waste and downtime, making processes more sustainable.

Tip: Consider how automation can streamline your production. Investing in tableting machines equipped with advanced analytics can lead to greater operational insights, enabling manufacturers to make informed decisions quickly.

Another trend is the move towards modular tableting systems, which offer flexibility in production. These systems allow manufacturers to customize processes based on specific product demands, which is particularly beneficial in a market that increasingly favors personalized medicine. The adaptability of modular machines ensures that pharmaceutical companies can respond efficiently to changing consumer needs.

Tip: Evaluate the scalability of your equipment. When choosing new tableting machines, look for options that can easily expand or modify as your production requirements evolve, ensuring long-term viability in a dynamic industry.

Related Posts

-

Mastering Natoli Tablet Press Techniques for Optimal Performance

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

How the Best Tablets Press Machine is Shaping the 2025 Industry Tech Landscape

-

How to Optimize Your Production Efficiency with a Tablet Presser for Maximum Yield

-

How to Optimize Your Manufacturing Process with a Tablet Presser

-

A Comprehensive Guide to the Best Tablet Presses for Global Buyers