Blog

Essential Tips for Choosing the Best Capsule Filling Plate for Your Needs

When it comes to the pharmaceutical and nutraceutical industries, the importance of precision and efficiency cannot be overstated. One essential tool that supports these industries in their capsule production processes is the Capsule Filling Plate. According to a recent market analysis by Grand View Research, the global capsule filling equipment market is anticipated to reach USD 1.53 billion by 2025, driven by rising health awareness and increasing demand for dietary supplements. This growth underscores the significant role that effective capsule filling solutions play in ensuring product quality and consistency.

Choosing the right Capsule Filling Plate is crucial for manufacturers aiming to optimize their production capabilities. A well-suited filling plate can enhance the efficiency of the filling process, reduce waste, and ensure accurate dosages, which is essential in maintaining compliance with industry regulations. Furthermore, data from the International Society for Pharmaceutical Engineering highlights that the efficiency of capsule filling machinery can be directly impacted by the design and material of the filling plates used. As the industry continues to evolve, understanding the key factors influencing the selection of a Capsule Filling Plate becomes increasingly essential for businesses looking to stay competitive and meet the demands of a growing market.

Understanding Capsule Filling Plates: Types and Uses

Capsule filling plates are essential tools in the pharmaceutical and supplement industries, enabling efficient and precise filling of capsules. Generally, these plates come in various types depending on the size, material, and configuration, catering to different production needs.

The primary types include manual, semi-automatic, and fully automatic plates, each offering distinct advantages.

Manual plates are cost-effective and best suited for small-scale operations, while semi-automatic plates are ideal for moderate production volumes, increasing efficiency without substantial investment.

Fully automatic filling systems, according to a report by Global Market Insights, are gaining popularity as they significantly enhance productivity, reduce human error, and optimize the filling process, particularly in large-scale manufacturing.

Additionally, various materials used in capsule filling plates play a crucial role in their functionality and durability.

Common materials include stainless steel, which offers resistance to corrosion and wear, and high-density polyethylene (HDPE), known for its lightweight and ease of cleaning.

A recent industry analysis revealed that 30% of manufacturers prefer stainless steel plates for their longevity and reliability.

Understanding the different types and materials of capsule filling plates can significantly impact the efficiency of capsule production, ensuring that businesses select the right tools to meet their specific operational needs and regulatory standards.

Key Factors to Consider When Choosing a Capsule Filling Plate

When selecting a capsule filling plate, several key factors should be thoroughly evaluated to ensure that it meets your specific needs. One of the most important considerations is the size and type of capsules you intend to use. Different capsules come in various dimensions, and the filling plate must be compatible with the chosen size to ensure optimal filling and sealing. Additionally, consider whether you need vegetarian capsules, as this may influence the type of filling plate that will work best for your applications.

Another critical factor is the material of the capsule filling plate. Plates made from high-quality materials are not only more durable but also easier to clean and maintain. Look for plates that are resistant to wear and tear, as this will extend their lifespan and improve your overall efficiency. Furthermore, the design of the plate should facilitate a smooth filling process, minimizing the risk of spills or inconsistencies during production. Considering these aspects will help you choose a filling plate that aligns with both your operational requirements and production goals.

Essential Tips for Choosing the Best Capsule Filling Plate for Your Needs

| Feature | Description | Importance |

|---|---|---|

| Material Quality | Choose durable and non-toxic materials for safety and longevity. | High |

| Size Compatibility | Ensure the plate matches the capsule size you intend to use. | High |

| Ease of Use | Look for intuitive designs that simplify the filling process. | Medium |

| Cleaning Process | Opt for plates that are easy to clean and maintain to ensure hygiene. | High |

| Production Capacity | Consider the volume of capsules you need to fill at once. | Medium |

| Price Point | Evaluate your budget against the features offered. | High |

Material Options for Capsule Filling Plates: Pros and Cons

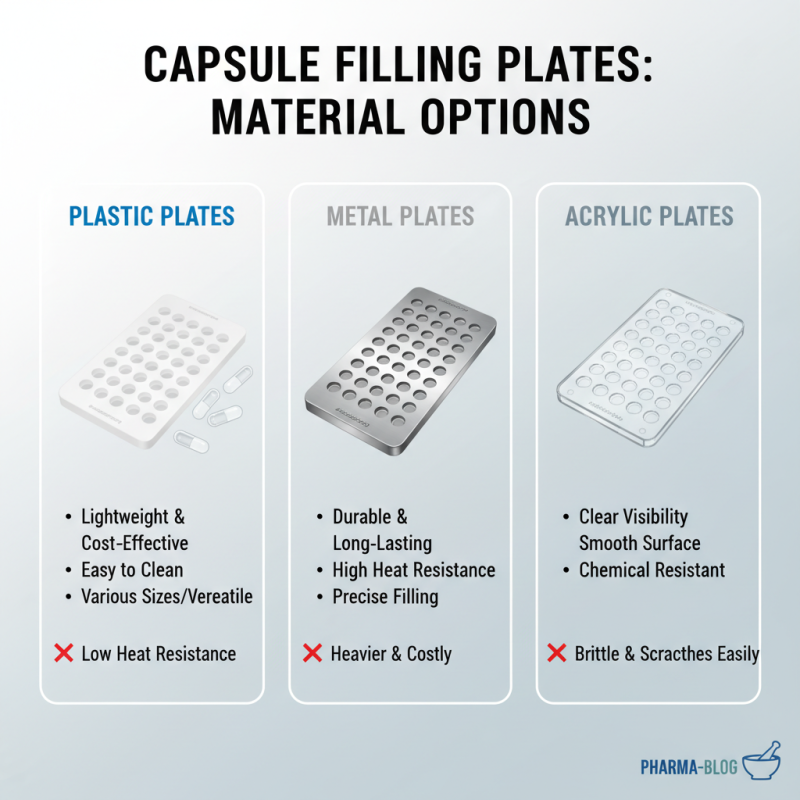

When selecting a capsule filling plate, understanding the material options available is crucial as each type offers distinct advantages and disadvantages. One common material is plastic, which is lightweight, cost-effective, and easy to clean. Plastic plates often come in various sizes, making them versatile for different capsule types. However, they may not withstand high temperatures as well as other materials, which can be a downside in certain filling processes.

Alternatively, metal plates, such as those made from stainless steel, provide durability and resistance to high temperatures, making them suitable for various applications. They are less prone to staining and can handle the wear and tear of frequent use. Nonetheless, metal plates tend to be heavier and may carry a higher price tag compared to their plastic counterparts. Additionally, the cleaning process can be more involved, requiring specific chemicals or methods to prevent corrosion and maintain the integrity of the surface.

In summary, the choice of material for a capsule filling plate significantly impacts your filling process. Assessing the pros and cons of plastic versus metal can guide you in making an informed decision that aligns with your specific needs, ensuring efficiency and quality in your capsule manufacturing.

Size and Capacity: Finding the Right Fit for Your Needs

When selecting a capsule filling plate, size and capacity are crucial factors to consider, as they directly affect the efficiency and outcome of your encapsulation process. Different applications may require varying quantities of capsules, so understanding your needs is essential. If you’re focusing on small batches—for instance, for personal use or product samples—a plate designed for fewer capsules, such as those filling 24 or 48 at a time, might be ideal. Conversely, for larger production runs or commercial purposes, opting for plates that accommodate 100 or more capsules at once will streamline your operation and save you valuable time.

Another aspect of size to keep in mind is the dimensions of the capsules themselves. Capsule filling plates come in different sizes tailored to various capsule dimensions, typically ranging from size "000" to "5." It’s critical to ensure that the plates you consider can accommodate the specific capsule sizes you intend to use. Moreover, factors like the plate's depth and diameter play a role in ensuring an easy and efficient filling process, reducing the chances of spillage or waste. By carefully evaluating the size and capacity of the capsule filling plate, you can achieve better results that align with your specific requirements.

Maintenance and Care Tips for Longevity of Capsule Filling Plates

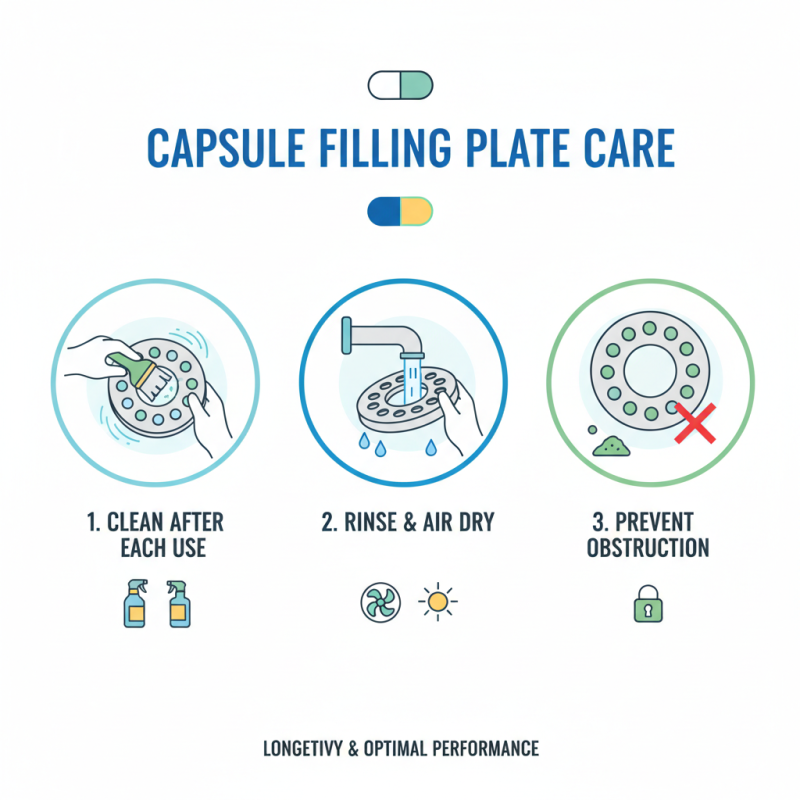

When it comes to maintaining your capsule filling plate, proper care is essential to ensure its longevity and optimal performance. One of the key maintenance tips is to clean the plate after each use. Residue from the filling process can accumulate and impact the efficiency of future batches. Utilize a soft brush and a non-abrasive cleaning solution to gently remove any leftover material, ensuring that no particles obstruct the filling holes. Additionally, rinse thoroughly with warm water and allow the plate to air dry completely before storing it.

Storage plays a crucial role in preserving the integrity of your capsule filling plate. Avoid placing heavy objects on top of it, as this can warp or damage the plate. Instead, store it in a cool, dry place away from direct sunlight. If possible, keep it in a protective case or pouch to prevent scratches and other potential harm. Regularly inspecting the plate for signs of wear or damage will assist in identifying any issues early on, allowing for timely repairs or replacements that can help extend its lifespan. Taking these steps will ensure that your capsule filling plate remains in peak condition for your future needs.

Related Posts

-

Unlocking Efficiency: The Ultimate Guide to Capsule Filling Plates for Optimal Productivity

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs

-

Ultimate Checklist for Selecting the Right Capsule Loader Machine for Your Production Needs

-

The Ultimate Guide to Choosing the Right Capsule Loader Machine for Your Business Needs

-

The Future of Capsule Packaging Machines in Sustainable Manufacturing

-

Unveiling the Future: How Capsule Loader Machines Are Revolutionizing Pharmaceutical Production with 30% Efficiency Gains