Blog

Ultimate Guide to Efficient Capsule Loader Machine Solutions for Your Production Needs

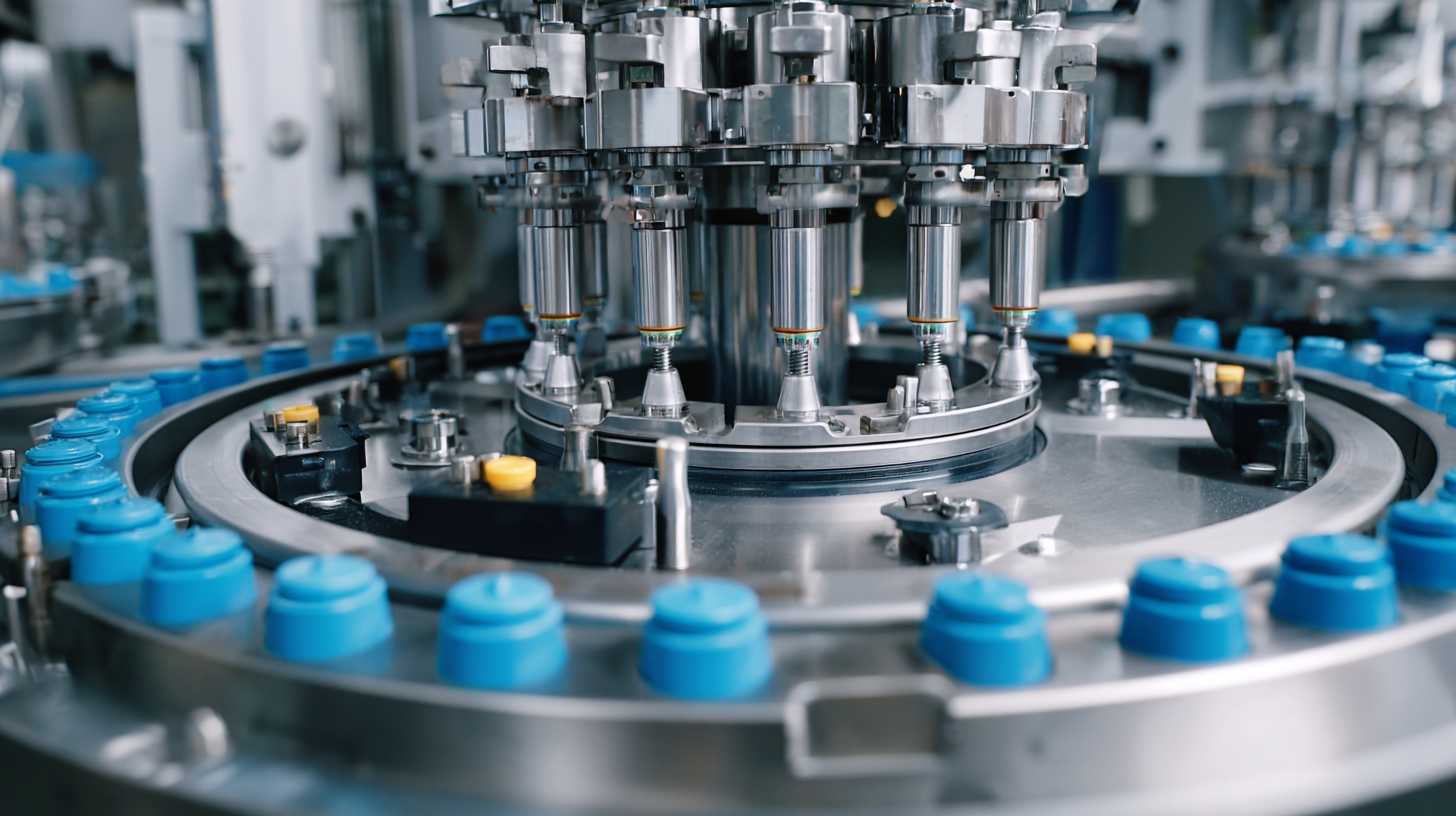

In the fast-paced world of manufacturing, ensuring optimal efficiency is paramount, especially when it comes to the use of a Capsule Loader Machine. These machines play a crucial role in the production line by streamlining the process of filling capsules with powders or granules, thus directly impacting productivity and product quality. However, as with any machinery, there are inherent challenges and issues that can arise, potentially hindering operations and resulting in costly downtime. In this ultimate guide, we will explore the common problems associated with Capsule Loader Machines and provide effective solutions tailored to address these challenges. Whether you are looking to improve your current systems or considering the integration of new machinery, understanding these key issues is essential for meeting your production needs efficiently and effectively.

Understanding the Basics of Capsule Loader Machines for Streamlined Production

Capsule loader machines play a crucial role in modern production lines, particularly in industries such as pharmaceuticals and nutraceuticals. Understanding the basics of these machines is essential for businesses looking to streamline their operations. A capsule loader machine automates the process of filling and sealing capsules, significantly reducing labor costs and increasing productivity. By utilizing advanced technology, these machines ensure consistent filling accuracy and quality, which are vital for maintaining regulatory standards and consumer trust.

Additionally, the efficiency of capsule loaders can be maximized by understanding their various components and functionalities. Key features to look for include adjustable filling volumes, user-friendly interfaces, and compatibility with a range of capsule sizes. Moreover, selecting a machine that offers easy maintenance and quick changeover capabilities can lead to improved workflow and reduced downtime. Investing in a high-performance capsule loader machine not only enhances the production process but also positions a company to meet growing market demands effectively.

Key Features to Look for in an Efficient Capsule Loader Machine

When selecting an efficient capsule loader machine, it's crucial to focus on key features that will enhance your production needs. First and foremost, consider the machine's speed and efficiency. Advanced machines on the market are designed to fill and seal a vast range of capsule types, making them adaptable to different formulations and scale requirements. High-speed solutions are particularly beneficial in the pharmaceutical and nutraceutical industries, where production rates can significantly affect profitability.

Another important feature to look for is precision in filling. The ability to achieve accurate dosing is vital for compliance and ensuring product quality. Equipment that uses advanced filling technologies, such as those utilizing tamping pin methods, can provide consistency while minimizing waste. Additionally, features like user-friendly interfaces and automated cleaning systems can save valuable time and labor costs, allowing manufacturers to focus on their core operations without compromising on quality or safety standards. These considerations are essential in navigating the complexities of capsule production effectively.

Step-by-Step Guide to Setting Up Your Capsule Loader for Optimal Performance

Setting up a capsule loader machine effectively is crucial for optimizing production performance in the pharmaceutical and nutraceutical industries. According to a recent report by MarketsandMarkets, the global capsule filling machine market is projected to reach USD 1.52 billion by 2026, highlighting the growing demand for efficient production solutions. To achieve this, operators must pay close attention to the setup process to ensure that the machine operates at peak efficiency.

The first step in setting up your capsule loader is to ensure compatibility with your specific capsule sizes and formulations. This involves selecting the right machine model that accommodates the desired capsule dimensions and fill types, which might include powders or granules. According to a technical paper published by the International Journal of Pharmaceutics, improper capsule loading techniques can lead to significant product loss, estimated at around 10-15%, during the filling process. Therefore, precise calibration and alignment are essential to minimize wastage and maximize productivity.

Next, conducting thorough maintenance checks before startup is vital. Regular maintenance can lead to a reduction in downtime by as much as 20%, as highlighted by a report from the Equipment Reliability Institute. Ensure that all mechanical components, such as the hopper, dosing system, and discharge mechanisms, are inspected and lubricated as needed. By following these systematic steps, manufacturers can ensure their capsule loader operates smoothly, leading to enhanced output and overall production efficiency.

Ultimate Guide to Efficient Capsule Loader Machine Solutions for Your Production Needs

| Feature | Benefits | Recommended Machine Type | Ideal Production Volume |

|---|---|---|---|

| Automatic Loading System | Increased efficiency and reduced manual labor | High-speed Capsule Loader | Over 200,000 capsules per month |

| Integrated Weighing System | Accurate dosage with minimal waste | Precision Capsule Loader | 100,000 to 200,000 capsules per month |

| Flexibility for Capsule Sizes | Versatile for different products | Multi-Format Capsule Loader | Up to 150,000 capsules per month |

| User-Friendly Interface | Simplifies operation and training | Semi-Automatic Capsule Loader | 50,000 to 100,000 capsules per month |

| Compact Design | Saves space in production area | Desktop Capsule Loader | Less than 50,000 capsules per month |

Common Challenges in Capsule Loading and How to Overcome Them

Capsule loading is a crucial step in the pharmaceutical and nutraceutical industries. However, several challenges often arise during this process. One common issue is the improper orientation of capsules, which can lead to delays and increased production costs. Implementing automated systems with advanced sensors can help identify and correct misaligned capsules, ensuring a smooth loading process.

Another significant challenge is the variability in capsule sizes and types. This variability can complicate the loading process and cause inconsistencies in the final product. To tackle this, investing in adjustable capsule loaders that can accommodate a range of sizes and shapes is essential. Furthermore, routine maintenance and calibration of loading equipment can bolster efficiency and minimize downtime, enabling manufacturers to meet production demands effectively. By proactively addressing these challenges, businesses can enhance their capsule loading systems and improve overall productivity.

Best Maintenance Practices to Extend the Life of Your Capsule Loader Machine

Maintaining the efficiency and longevity of your capsule loader machine is crucial for optimizing production processes. Implementing best practices for maintenance can significantly extend the life of your equipment. Regular cleaning is essential; much like other machines, a clean capsule loader operates more efficiently and prevents potential breakdowns. Monitoring and replacing worn parts before they fail can save time and costly repairs, ensuring that your production runs smoothly without interruptions.

Incorporating advanced technologies, such as magnetic filtration systems, can also enhance the durability of your capsule loader. These systems capture contaminants, thereby protecting critical hydraulic components and contributing to longer machine life. Additionally, planning for timely rebuilds is a proactive strategy that can significantly decrease total ownership costs while maximizing the performance of your equipment. By implementing these strategies, you can not only ensure the smooth operation of your capsule loader but also enhance its lifespan, providing a reliable solution for your production needs.