Blog

How to Use a Fluidized Bed Processor Effectively?

The Fluidized Bed Processor is a vital technology in various industries, particularly in pharmaceuticals and food processing. According to a report by MarketsandMarkets, the global fluidized bed systems market is projected to reach $1.7 billion by 2026. This growth reflects the increasing demand for efficient processing solutions.

Effective use of a Fluidized Bed Processor can enhance product consistency and reduce processing times. However, challenges remain. For instance, not all materials behave predictably in a fluidized state. It’s essential to understand the properties of the powders being processed. Inadequate conditions may lead to inconsistencies in product quality. A component’s particle size and distribution significantly influence the results.

Moreover, operational parameters must be regularly reviewed and adjusted. Miscalculations can result in inefficient processing. Training operators is crucial. They need to be aware of potential pitfalls to optimize performance. Investing in a Fluidized Bed Processor can bring benefits, but it requires understanding and careful management. The complexity of this technology demands an informed approach to achieve desired outcomes.

Understanding the Basics of Fluidized Bed Processors

Fluidized bed processors play a critical role in various industries, particularly in pharmaceuticals and food processing. They provide efficient mixing and heat transfer. The technology involves suspending solid particles in a gas or liquid, creating a fluid-like state. This unique characteristic allows for uniformity in processing materials.

According to a recent industry report from MarketsandMarkets, the fluidized bed technology market is expected to reach USD 46.4 billion by 2026. This growth indicates a strong trend toward automation and improved processing efficiency. Understanding the basics helps in optimizing performance. Managing parameters such as temperature, airflow, and feed rate is essential. Small deviations can lead to significant issues in product quality and efficiency.

Tips: Monitor particle size closely. Incorrect sizes can lead to uneven fluidization. Regular maintenance of equipment is crucial. Wear and tear can affect efficiency and lead to suboptimal results. Use quality materials to prevent contamination. Remember, training staff on best practices is vital for maximizing the benefits of fluidized bed processors.

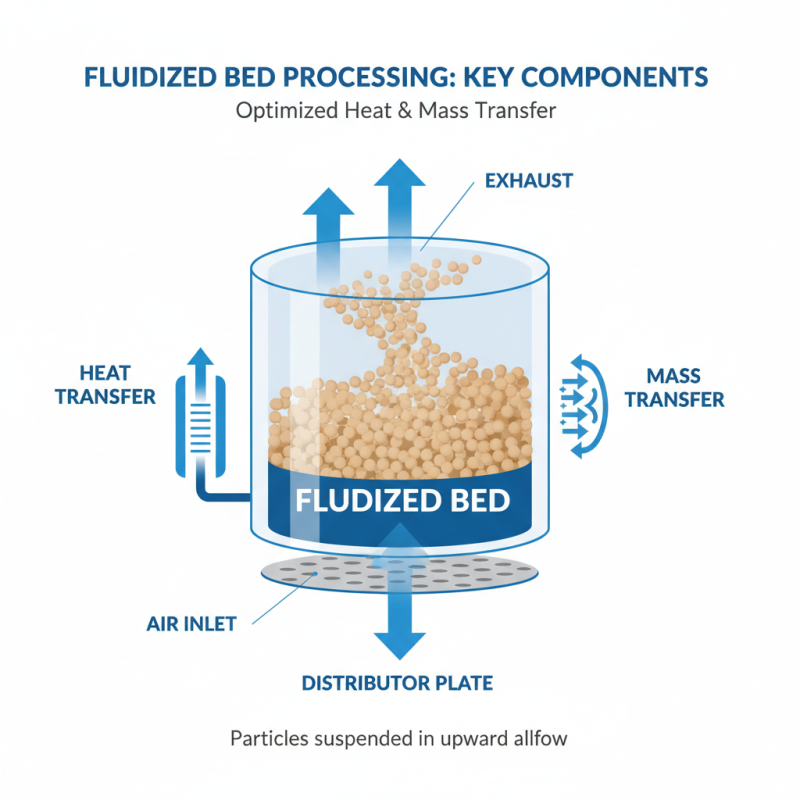

Key Components and Their Functions in Fluidized Bed Processing

Fluidized bed processing is a popular method in various industries. Understanding its key components is essential for effective operation. The bed itself is where the magic happens. It consists of particles that are suspended in an upward flow of air. This creates a fluid-like state, allowing for better heat and mass transfer.

The distributor plate is another crucial part. It ensures even airflow through the bed. Without it, some areas might overheat while others remain under-processed. Monitoring airflow is vital to maintain uniformity. If the distribution is uneven, it can lead to inefficient processing. Operators might need to adjust the airflow frequently.

The fluidization chamber plays a significant role too. Its design impacts how particles behave. A well-designed chamber promotes uniform mixing. However, if not properly calibrated, it can lead to clumping or channeling. Regular evaluation of chamber performance can reveal issues early on. Operators must remain vigilant to optimize processing efficiency. Feedback and adjustments are necessary for improving outcomes.

Steps to Optimize Fluidization for Improved Processing Efficiency

Fluidized bed processors can improve processing efficiency significantly. To optimize fluidization, precise control is key. Understanding particle size distribution is crucial. Studies show that uniform particle size leads to better fluidization. For instance, a report by the National Institute of Standards and Technology indicates that particles in the range of 50-100 microns perform optimally. Larger or smaller particles may not fluidize properly, leading to inefficiencies.

Adjusting the airflow rates also plays a critical role. The wrong airflow can cause channeling. This occurs when air flows through part of the bed only, leaving other areas inactive. According to industry data, achieving a uniform velocity across the fluidized bed can reduce energy costs by up to 15%. Experimenting with airflow rates helps to find the sweet spot for specific materials.

Regular maintenance of the equipment is often overlooked. Dust buildup can disrupt fluidization. A clean processor allows for optimal performance, which is often neglected in many facilities. Operators sometimes ignore this, leading to decreased efficiency. Monitoring equipment performance regularly can provide valuable insights, helping to identify when adjustments are necessary. Continuous reflection on these aspects can lead to significant improvements in fluidized bed processing.

How to Use a Fluidized Bed Processor Effectively? - Steps to Optimize Fluidization for Improved Processing Efficiency

| Step | Description | Key Factors | Expected Outcome |

|---|---|---|---|

| 1 | Prepare the Material | Particle Size, Density | Uniform Fluidization |

| 2 | Set Up the Equipment | Airflow Rate, Pressure | Optimal Processing |

| 3 | Monitor Fluidization | Temperature, Humidity | Consistent Quality |

| 4 | Adjust Parameters | Flow Rate, Bed Height | Enhanced Efficiency |

| 5 | Conduct Quality Control | Sampling, Testing | Product Consistency |

Common Challenges in Fluidized Bed Processing and Their Solutions

Fluidized bed processing can present a range of challenges. One common issue is uneven distribution of particles. This can lead to poor processing efficiency. To tackle this, ensure the fluidization air flow is consistent. Adjust the airflow rate based on the material's properties for optimal results.

Another challenge is the risk of agglomeration. When particles clump together, they hinder fluidization. This can create dead zones in the bed. Regularly monitor the moisture content of your material. Keeping it within the right range can mitigate agglomeration.

**Tips:** Always pre-screen your materials. This minimizes the risk of oversized particles. Additionally, consider using particle size analyzers for better control. Regular maintenance of your equipment is crucial. It prevents wear and tear, which can impact performance. Remember, experimentation leads to better understanding, but don’t ignore past mistakes. Reflect on what went wrong to improve your future processes.

Best Practices for Maintenance and Safety in Fluidized Bed Operations

Fluidized bed processors are powerful tools in various industries. However, maintenance and safety practices are crucial for optimal performance. Regular inspections can prevent costly downtimes. Reports indicate that poorly maintained equipment can reduce efficiency by up to 30%.

**Tips:** Inspect wear components regularly. This can reduce unexpected failures. Always check for fluidized bed consistency. It helps maintain effective processing.

Safety is paramount in fluidized bed operations. Operators should be trained to recognize potential hazards, such as excessive pressure buildup, which can lead to catastrophic failures. OSHA statistics show that improper handling of fluidized beds accounts for a significant percentage of accidents in manufacturing settings.

**Tips:** Implement a clear safety protocol. Encourage open communication among team members. Awareness can significantly enhance safety measures.

Evaluate the design of your fluidized bed system. Ineffective configurations can lead to suboptimal performance. Sometimes, minor design adjustments greatly enhance efficiency and safety. Always seek feedback from operators. Their insights can reveal areas needing improvement.

Fluidized Bed Processor Performance Metrics

This chart illustrates key optimization parameters in fluidized bed processing operations. Maintaining ideal airflow rates, particle size, temperature, residence time, and moisture content is essential for effective processing.

Related Posts

-

The Ultimate Guide to Mastering Fluidized Bed Processors for Efficient Material Processing

-

Understanding the Role of Fluidized Bed Processors in Modern Pharmaceutical Manufacturing

-

What is a Fluidized Bed Processor and How Does It Work for Efficient Material Processing?

-

How to Choose the Right Capsule Filling Equipment for Your Business Needs

-

Unveiling the Future: How Capsule Loader Machines Are Revolutionizing Pharmaceutical Production with 30% Efficiency Gains

-

Best Capsule Filling Plate for Efficient Home Use?