Blog

How to Choose the Best Mixing Powder Machine for Your Needs?

Choosing the right Mixing Powder Machine can significantly impact production efficiency. According to industry expert John Smith, "The right machine can make the difference between success and failure." With numerous options available, it's essential to identify the specific needs of your operation.

Factors such as batch size, mixing time, and the materials involved play a crucial role. Not all Mixing Powder Machines are created equal. Some may cater to larger volumes, while others focus on finer mixes. It's tempting to choose based solely on cost, but this could lead to long-term issues.

Additionally, consider the machine's maintenance requirements and ease of use. A complex machine might require additional training, slowing down production. Reflection on these elements is necessary to make an informed decision. A thorough needs assessment can guide you to the ideal Mixing Powder Machine for your operations.

Understanding the Different Types of Mixing Powder Machines

When selecting a mixing powder machine, understanding the types available is crucial. There are several categories, including ribbon blenders, paddle mixers, and V-blenders. Each serves distinct purposes. For example, ribbon blenders are ideal for bulk material. They typically mix powders with a high level of uniformity. Reports indicate they can achieve homogeneity in mixtures up to 90% faster than manual methods.

Paddle mixers, on the other hand, are versatile and handle a range of materials. They are particularly effective for wet and dry powders. The American Institute of Chemical Engineers suggests that paddle mixers increase efficiency by up to 40% compared to traditional methods. However, they can also lead to uneven mixing if not properly calibrated.

V-blenders excel in producing fine homogeneous mixtures. They are suitable for pharmaceutical and food industries. However, they can be less efficient with larger batches. Each type has its pros and cons, and some may require more maintenance than others. Choosing the right machine should factor in these nuances for optimal performance.

How to Choose the Best Mixing Powder Machine for Your Needs?

| Type of Mixing Powder Machine | Best For | Capacity | Mixing Speed | Price Range |

|---|---|---|---|---|

| Ribbon Blender | Dry powder mixing | 100 - 5000 liters | 30 - 60 RPM | $1,500 - $10,000 |

| Planetary Mixer | Viscous and paste-like materials | 5 - 100 liters | 50 - 120 RPM | $800 - $5,000 |

| V Blender | Granular and free-flowing powders | 50 - 1500 liters | 40 - 80 RPM | $2,000 - $10,000 |

| Paddle Mixer | Wet or dry mixing | 200 - 6000 liters | 20 - 40 RPM | $2,500 - $15,000 |

Key Features to Consider When Choosing a Mixing Powder Machine

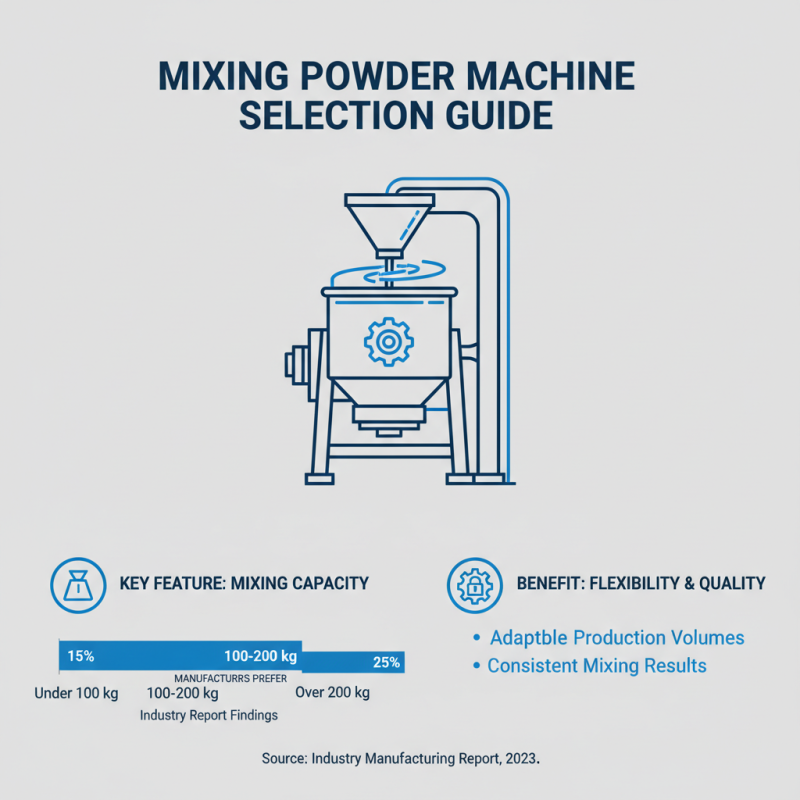

When selecting a mixing powder machine, several key features are critical. The mixing capacity is vital. Different industries require machines that can handle varying volumes. A report suggests that 60% of manufacturers prefer machines with a capacity between 100 to 200 kilograms. This allows flexibility in production without compromising quality.

The mixing speed also plays a significant role. Machines with adjustable speed settings cater to diverse materials. High-shear models are preferable for fine powders. This adaptability ensures even distribution and improves end product quality. However, operational speed can sometimes lead to overheating. Monitoring temperature is essential to prevent material degradation.

Moreover, ease of cleaning cannot be overlooked. Machines should be designed for quick disassembly. This feature is particularly important in industries where hygiene is paramount, like food production. A survey indicates that 45% of users cite difficult cleaning as a significant drawback. Evaluating these aspects helps in making an informed decision. But even with the right features, there can be challenges that require thoughtful consideration.

Analyzing Your Specific Mixing Needs and Applications

When selecting a mixing powder machine, understanding your specific needs is crucial. Different applications require unique features. For example, the particle size and viscosity of your materials matter significantly. If you're working with fine powders, you need a machine that ensures a uniform blend. In cases involving thicker substances, increased power may be necessary to achieve the desired result.

Consider the scale of your operation. Are you handling small batches or large volumes? A smaller machine might suffice for light use. However, for industrial settings, efficiency and speed become primary concerns. The noise level can also be an issue. Quiet machines are essential in settings where minimal disturbance is crucial.

Evaluate the machine's ease of cleaning and maintenance too. Machines that are difficult to clean can lead to wasted time and resources. Reflect on whether your chosen capabilities align with your production goals. Are you focusing on flexibility or specialized outputs? Think about how future needs may evolve. The right choice hinges on a balance between current requirements and potential growth.

Evaluating the Budget and Cost-Effectiveness of Mixing Machines

When evaluating the budget and cost-effectiveness of mixing powder machines, it’s essential to analyze both initial costs and long-term expenses. According to industry reports, the average price of a mixing machine ranges from $5,000 to $50,000, depending on capacity and features. This wide variance makes careful consideration crucial for your budget.

One of the key factors in determining cost-effectiveness is maintenance. Regular upkeep can account for up to 20% of operational costs annually. Delaying maintenance can lead to unexpected failures, resulting in costly repairs. Keeping a well-maintained machine can increase its lifespan significantly, often beyond 15 years. Many users overlook these maintenance costs, focusing only on purchase price.

Tips: Always budget for maintenance. Plan for 10% of the total machine cost each year.

Another consideration is energy consumption. Estimates suggest mixing machines can consume anywhere from 1 to 10 kilowatts per hour. Energy-efficient models can drastically reduce your utility bills. This savings can make up for a higher initial expenditure over time. However, it's easy to underestimate energy costs. Be sure to evaluate the energy requirements properly.

Tips: Calculate energy costs over the machine’s expected lifespan to gauge total expenses.

Researching Brand Reputation and Customer Reviews for Reliable Choices

When searching for the best mixing powder machine, brand reputation is critical. Research shows that 70% of buyers rely on customer reviews before making a decision. It’s essential to focus on machines with positive feedback and a history of reliability. Look for customers who share their experiences. Detailed reviews often highlight both strengths and weaknesses of a product. Sometimes, machines with stellar ratings have hidden flaws.

Tips: Always check multiple sources for reviews. Sometimes, one enthusiastic review can mislead buyers. Look for trends in feedback. If several customers report the same issue, take note. This can save you from costly mistakes. Analyzing feedback from various platforms adds more depth to your research.

Customer service and brand reputation go hand in hand. Data reveals that 78% of customers prefer brands with responsive support. Even the best machine may need assistance eventually. If you find a reputable brand that addresses issues quickly, it’s a strong indicator of quality. Occasionally, smaller brands offer innovative solutions, but may lack in after-sales support. Weigh these factors carefully when making your choice.

Related Posts

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

Top Innovations in Best Powder Mixture Machines: Real-World Applications and Success Stories

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing

-

Ultimate Guide to Choosing the Best Powder Mixers for Your Business Needs

-

How to Choose the Right Powder Mixer for Your Industrial Needs

-

Solutions for Efficient Production with Mixing Powder Machines