Blog

How to Choose the Right Tablets Press Machine for Your Production Needs

Choosing the right Tablets Press Machine is a critical decision for any production facility focused on manufacturing high-quality tablets efficiently. With a diverse range of models available on the market, understanding the various features and specifications of these machines is essential for meeting specific production demands. The right press machine not only impacts the quality of the final product but also influences operational efficiency, production volume, and overall costs.

When selecting a Tablets Press Machine, it's important to assess your production needs thoroughly. Factors such as tablet size, shape, and hardness, as well as the scale of production, should guide your choice. Additionally, considerations like maintenance requirements, ease of use, and availability of technical support play a vital role in ensuring your investment translates into a smooth and efficient manufacturing process. By carefully evaluating these aspects, manufacturers can select a Tablets Press Machine that not only aligns with their current production goals but is also versatile enough to adapt to future needs.

Identifying Your Production Requirements for Tablets Press Machines

When selecting a tablets press machine, the first step is to clearly identify your specific production requirements. This involves assessing the type of tablets you intend to produce, including their size, shape, and composition. Understanding the material properties is crucial, as different formulations may necessitate distinct compression forces or tooling configurations. Moreover, consider the expected production volume; a high-output requirement may dictate the need for a more robust machine capable of operating at optimal speeds without compromising quality.

In addition to material and volume, evaluate the operational environment where the tablets press machine will be located. Factors such as available space, maintenance capabilities, and operator expertise will influence your choice. Machines designed for ease of cleaning and maintenance can save time and reduce downtime. Likewise, ensuring that the equipment can accommodate future expansions in production capabilities will provide greater flexibility in an evolving manufacturing landscape. Careful consideration of these parameters will enable you to choose a tablets press machine that not only meets your current needs but also supports future growth.

How to Choose the Right Tablets Press Machine for Your Production Needs

| Production Requirement | Recommended Machine Type | Key Features | Output Capacity (tablets/hour) | Typical Applications |

|---|---|---|---|---|

| Low Volume Production | Single Punch Tablet Press | Manual Operation, Simple Changeover | 500 - 1,000 | Research & Development, Small Batch Production |

| Medium Volume Production | Rotary Tablet Press | Continuous Production, Multiple Punch Stations | 1,000 - 10,000 | Pharmaceuticals, Nutraceuticals |

| High Volume Production | High-Speed Tablet Press | Advanced Automation, High Efficiency | 10,000 - 50,000 | Large Scale Manufacturing, Consumer Goods |

| Specialty Tablets | Double-Sided Tablet Press | Allows for Complex Shapes, Custom Designs | 1,000 - 5,000 | Niche Markets, Special Formulations |

Evaluating Different Types of Tablet Press Machines Available

When selecting the right tablet press machine for your production needs, it is crucial to evaluate the various types available in the market. The two primary categories are single-station and multi-station press machines. Single-station machines, such as those used in laboratory settings, are ideal for small-scale production and formulation studies, offering flexibility in adjusting tablet formulations. In contrast, multi-station machines are designed for high-volume manufacturing, capable of producing thousands of tablets per hour. According to a recent market research report by Grand View Research, the global tablet press machine market is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028, indicating a rising demand for efficient and reliable machinery in pharmaceutical and nutraceutical industries.

Furthermore, the type of tooling used in tablet press machines also plays a vital role in production efficiency. Standard tooling can be cost-effective for short runs, while custom tooling provides more options for unique tablet designs and manufacturing processes. It is important to evaluate the compatibility of the machine with your desired tablet size and shape, as well as material handling capabilities. The same market report noted that approximately 28% of tablet manufacturers prioritize tooling as a critical factor in their purchasing decisions, highlighting the importance of this aspect in optimizing production workflows.

Key Features to Consider in Tablet Press Machines

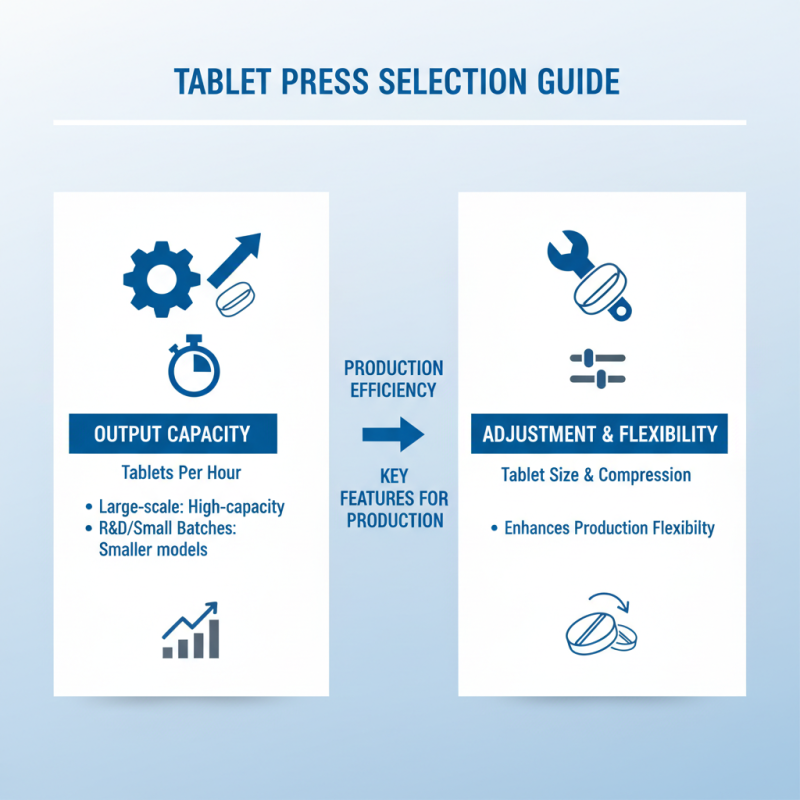

When selecting a tablet press machine, understanding the key features is essential for meeting your production needs. One of the most important aspects to consider is the machine’s output capacity. This relates to the number of tablets it can produce per hour, which will directly affect your production efficiency. High-capacity machines are ideal for large-scale manufacturing, while smaller models may be more suitable for research and development or smaller batches. Additionally, assessing the adjustment capabilities of the machine for tablet size and compression settings can enhance flexibility in production.

Another critical feature is the machine’s ease of operation and maintenance. User-friendly controls and automated functions can significantly reduce labor costs and training time. Look for machines with clear interfaces that allow for quick setup and modification during production runs. Maintenance features like easy access to key components for cleaning and repairs are also vital, as they minimize downtime and keep operations running smoothly. Finally, consider the robustness of the machine—durable materials and reliable engineering techniques can influence the longevity and performance of the tablet press, ensuring it can withstand the demands of high-volume production.

Assessing the Cost and Budget for Tablet Press Machines

When evaluating the cost and budget for tablet press machines, it's essential to consider not only the initial purchase price but also the long-term operational costs. High-quality machines may come with a higher upfront cost, but they often translate to lower maintenance expenses and better efficiency over time. Therefore, it's crucial to analyze your production requirements to find a balance between quality and affordability that aligns with your business goals.

Tips: Before making a purchase, conduct a thorough market analysis to compare prices and features of different machines. Look for reputable suppliers who offer warranty and after-sale support, as this will help ensure that you are making a sound investment.

It's also wise to factor in additional costs associated with installation, training, and any potential upgrades in the future. Some machines may require specialized training for your staff, which can add to overall expenses. Setting a clear budget that accommodates these factors will help you avoid unexpected financial strains and choose a tablet press machine that truly meets your production needs.

Tips: Always keep a contingency fund for any unforeseen expenses that may arise during operation. This will provide a safety net and help maintain a smooth production process without financial interruption.

Understanding Maintenance and Support for Tablet Press Machines

When selecting a tablet press machine for production, understanding maintenance and support is crucial to ensure optimal performance and longevity. Regular maintenance is essential; data indicates that improper maintenance can reduce equipment efficiency by up to 30%. Operators should be well-versed in daily, weekly, and monthly maintenance routines, which typically include cleaning, lubrication, and inspections of key components. A comprehensive maintenance schedule not only extends the life of the machine but also minimizes unplanned downtime, which can be particularly costly in the pharmaceutical industry, where the average cost of downtime can exceed $500,000 per hour.

Additionally, reliable support services are indispensable. Industry reports suggest that up to 70% of manufacturers find technical support plays a significant role in their purchasing decisions for machinery. Access to knowledgeable technicians and readily available spare parts can dramatically influence production timelines. Companies should inquire about the availability of technical support during off-hours, as this can be critical for addressing urgent maintenance needs. Furthermore, investing in machines that come with detailed operational manuals and training resources can empower operators and reduce reliance on external support, ultimately enhancing production efficiency.

Related Posts

-

How to Use a Tablet Presser for Effective Tablet Making Techniques

-

Ultimate Guide to Choosing the Best Tablets Press Machine for Your Production Needs

-

How to Optimize Your Production Efficiency with a Tablet Presser for Maximum Yield

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

The Evolution of Tableting Machines in Modern Pharmaceutical Manufacturing

-

A Comprehensive Guide to the Best Tablet Presses for Global Buyers