Blog

How to Choose the Right Capsule Filling Equipment for Your Business Needs

In the pharmaceutical and nutraceutical industries, the demand for high-quality capsule filling equipment has surged significantly. Recent market analysis from industry reports indicates that the global capsule filling equipment market is projected to grow at a CAGR of 7.3% from 2023 to 2030, driven by the increasing prevalence of chronic diseases and the subsequent rise in demand for effective dosage forms. In this competitive landscape, selecting the right Capsule Filling Equipment is crucial for businesses aiming to optimize their production efficiency and ensure product quality.

According to Dr. Samuel Roberts, a leading expert in pharmaceutical manufacturing, “The choice of capsule filling equipment not only affects production rates but also impacts the overall reliability of the drug delivery system.” His insights underline the importance of understanding specific business needs, whether it be small-scale production for niche products or high-volume output for larger markets. Choosing the appropriate equipment requires careful consideration of various factors, including production capacity, ease of use, and adaptability to different formulations, all of which play a vital role in meeting regulatory standards and consumer expectations. As the industry evolves, aligning the choice of Capsule Filling Equipment with strategic business goals will be paramount for sustained success.

Identifying Your Business Requirements for Capsule Filling Equipment

When selecting capsule filling equipment, it's crucial to first identify your specific business requirements. Consider factors such as production capacity, the types of capsules needed, and the formulation you are working with. Understanding these requirements will help you narrow down the options and make informed decisions about the equipment that best fits your operations.

**Tips:** Start by assessing your production volume. If you anticipate a high demand, look for equipment that can accommodate larger batches while maintaining efficiency and quality. For businesses focused on supplements or pharmaceuticals, compatibility with various formulations—like powders or granules—should also be prioritized to ensure versatility.

Additionally, evaluate the level of automation you need. For smaller operations, semi-automatic machines may suffice, while larger businesses might require fully automatic systems to optimize productivity. Maintenance and ease of operation should not be overlooked; select equipment that aligns with your team's skill level and technical expertise.

**Tips:** Consult with your team members who will operate the equipment to gather insights about their needs and preferences. Their feedback can highlight essential features and functions that are vital for daily operations. Finally, consider the scalability of the equipment; choose machinery that can grow with your business to avoid unnecessary future investments.

Understanding Different Types of Capsule Filling Machines

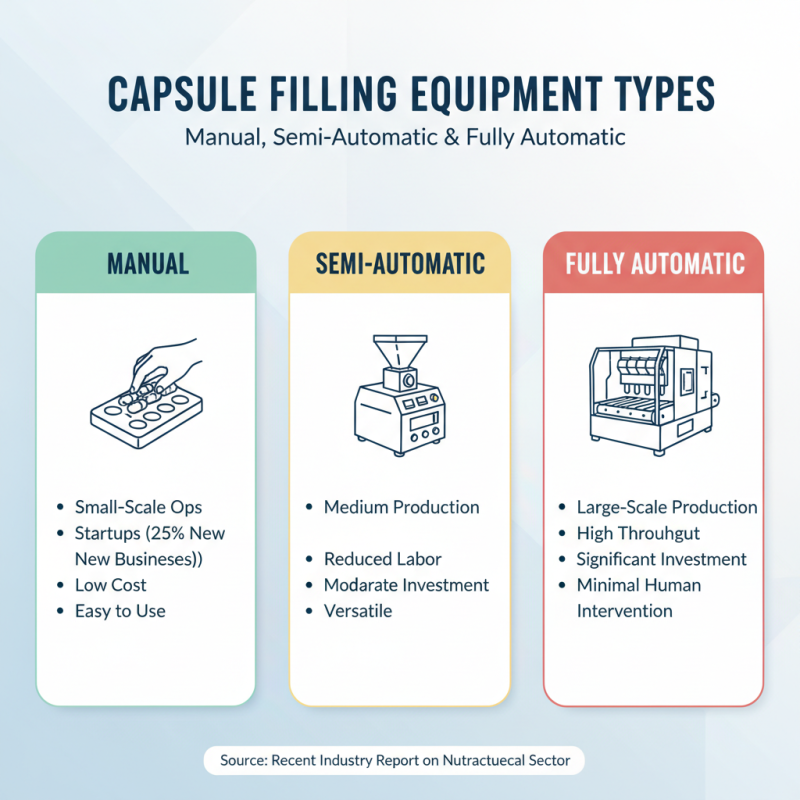

When selecting the appropriate capsule filling equipment, understanding the different types of capsule filling machines available in the market is critical. The three primary types are manual, semi-automatic, and fully automatic machines. Manual capsule fillers are often used by small-scale operations and pharmaceutical startups due to their low cost and ease of use. According to a recent industry report, approximately 25% of new businesses in the nutraceutical sector start with manual machines to keep initial investment costs down.

Semi-automatic machines offer a balance between production speed and labor cost, making them popular among mid-sized companies. These machines can fill a range of capsule sizes and are versatile, enabling manufacturers to switch between formulations without significant downtime. Data from the Capsule Filling Machines Market Research Report suggests that the semi-automatic category is expected to witness a compound annual growth rate (CAGR) of 4.5% over the next five years, driven by increasing demand for custom formulations and batch processing.

Fully automatic machines are the cornerstone of large-scale manufacturing due to their high efficiency and output rates. They can achieve production levels exceeding 100,000 capsules per hour, catering to the vast demand in the pharmaceutical and dietary supplement industries. The same industry report highlights that the fully automatic segment is projected to account for over 50% of the market share by 2028, as companies continuously seek to enhance productivity and minimize human error in their operations. Understanding these distinctions can help businesses align their production capabilities with their specific operational needs.

Evaluating Production Capacity and Efficiency Needs

When selecting capsule filling equipment, evaluating production capacity and efficiency needs is crucial for ensuring optimal performance in your business. Start by assessing the scale of your operations; understanding whether you are a small startup or an established manufacturer can help you determine the right equipment size and type. For smaller operations, machines with lower output rates may be sufficient, allowing for flexibility in production runs and minimizing upfront investment costs. Conversely, larger businesses may require high-capacity machines that can sustain continuous production to meet high demand without compromising on quality.

Efficiency is not just about speed; it also involves the ability to maximize output while minimizing waste and downtime. Look for capsule filling machines that offer features such as automation, quick changeover capabilities, and user-friendly interfaces. These features can significantly enhance throughput and reduce labor costs. Additionally, consider the versatility of the equipment—machines that can handle a variety of capsule sizes and formulations might be more beneficial in adapting to changing market needs and product offerings. Prioritizing these aspects will ensure that the chosen equipment aligns with your business goals and supports sustainable growth.

Assessing Budget Constraints and Investment Returns

When selecting capsule filling equipment, one of the most important considerations is understanding your budget constraints. The initial investment can vary significantly based on the technology and capabilities of the equipment. It's crucial to conduct a

thorough assessment of both your financial capacity and the potential costs associated with the equipment, including maintenance and operational expenses. A well-defined budget will not only guide your purchase but also help you avoid overspending on features that may not be necessary for your business.

In addition to budget considerations, evaluating the expected return on investment (ROI) is essential. The right capsule filling machine can enhance production efficiency, reduce labor costs, and improve product consistency, all of which contribute to profitability.

To estimate ROI, consider factors such as increased production volume, savings on manual labor, and the potential for higher product quality leading to customer satisfaction. By balancing upfront costs against these long-term benefits, businesses can make informed decisions that align with their operational needs and financial goals.

Considering Maintenance and Support Options for Equipment

When selecting capsule filling equipment, it is crucial to pay attention to maintenance and support options, as these factors can significantly affect the longevity and efficiency of your machinery. According to a report by the International Society for Pharmaceutical Engineering (ISPE), proper maintenance can reduce machine downtime by as much as 25% and increase overall productivity. Regular maintenance not only extends the lifespan of your equipment but also ensures that it operates at optimal performance levels, which is essential for maintaining product quality and compliance with industry standards.

In addition to scheduled maintenance, the availability of technical support is a vital consideration. A study published in the Journal of Pharmaceutical Innovation highlighted that companies with robust support systems tend to experience fewer operational disruptions, helping to keep production schedules on track. Choosing equipment from manufacturers that offer comprehensive training programs and responsive customer service can further enhance your team’s ability to troubleshoot issues quickly, thereby minimizing potential losses during production. Investing time in understanding the maintenance and support structures of potential capsule filling equipment will ultimately lead to more informed decisions and better operational efficiency for your business.

How to Choose the Right Capsule Filling Equipment for Your Business Needs - Considering Maintenance and Support Options for Equipment

| Equipment Type | Production Capacity (Capsules/hr) | Maintenance Frequency (Months) | Support Options | Cost Range ($) |

|---|---|---|---|---|

| Semi-Automatic | 1,000 - 3,000 | 6 | Online, Phone Support | 2,000 - 5,000 |

| Fully Automatic | 5,000 - 20,000 | 12 | Onsite, Extended Warranty | 10,000 - 50,000 |

| Manual | 500 - 1,000 | 3 | Email Support | 500 - 2,000 |

| High-Speed | 20,000 - 50,000 | 18 | 24/7 Phone Support | 50,000 - 150,000 |

Related Posts

-

Step-by-Step Guide to Mastering Capsule Filling Equipment: Tips and Techniques

-

What is Capsule Filling Equipment and Its Impact on Pharmaceutical Production Efficiency?

-

Unlocking Efficiency: How Capsule Filling Equipment Revolutionizes the Supplement Industry

-

Elevating Manufacturing Standards with the Best Capsule Loader Machine

-

How to Choose the Right Capsule Loader Machine for Your Business Needs

-

Unlocking Efficiency: The Ultimate Guide to Capsule Filling Plates for Optimal Productivity