Blog

Why Choose a Capsule Loader Machine for Your Business Needs?

In today's fast-paced business environment, efficiency is critical. Investing in a Capsule Loader Machine can streamline your operations significantly. Dr. John Smith, an industry expert in automation, once stated, "A Capsule Loader Machine enhances productivity while maintaining quality." This insight highlights the importance of such technology in modern businesses.

Many companies face challenges with manual loading processes. These problems often lead to errors and wasted resources. A Capsule Loader Machine can help eliminate these issues by providing consistency and precision. Imagine a production line where every capsule is filled accurately, reducing the need for manual intervention.

However, it is essential to consider the initial investment and maintenance costs of a Capsule Loader Machine. While it offers numerous advantages, companies should evaluate their specific needs. Balancing benefits with potential drawbacks is crucial for making the right decision. Investing in the right technology can be transformative, but it requires careful thought and planning.

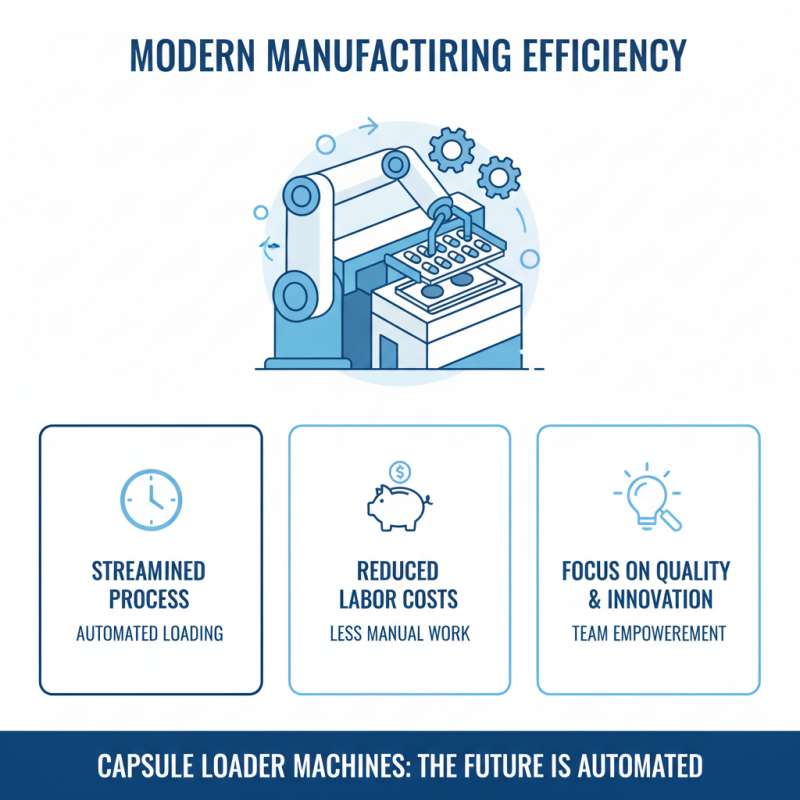

Benefits of Using Capsule Loader Machines in Modern Manufacturing

In modern manufacturing, efficiency is key. Capsule loader machines streamline the process significantly. They automate the loading of capsules, reducing labor costs. This means your team can focus on quality control and innovation.

One major benefit is speed. A capsule loader can fill thousands of capsules in a short time. This keeps up with high demand. It also minimizes human error, which can lead to costly mistakes. However, some machines may require regular maintenance. This can interrupt production if not planned properly.

Here are some tips to consider. Make sure to train your staff on the machine’s operation. Misuse can lead to breakdowns. Regular checks can prevent surprises. Additionally, think about the scalability of the machine. As your business grows, your equipment should grow with it. Capsule loader machines can adapt when you choose the right model.

Key Features and Technologies Behind Capsule Loader Machines

Capsule loader machines are essential for businesses looking to enhance efficiency. These machines offer several key features that simplify the capsule filling process. For instance, automatic loading systems minimize human error. They enhance accuracy and reduce contamination risks. A significant aspect is their ability to handle various capsule sizes, catering to diverse product ranges.

Modern capsule loaders utilize advanced technologies to optimize speed and performance. Many machines feature touch screen interfaces, which allow for easy adjustments. Operators can quickly set parameters, reducing downtime. Furthermore, some models include sensors that track capsule positions, ensuring smooth operations.

However, businesses must remain vigilant about maintenance. Regular checks are necessary to ensure longevity and consistent performance.

Employing a capsule loader machine can transform production lines. While these machines provide numerous benefits, they also require investment and training. It’s vital for companies to assess their specific needs. Taking time to evaluate machine capabilities can be crucial. A thoughtful approach to integrating new technology can lead to substantial improvements in workflow and productivity.

Industry Statistics on Productivity Improvements with Capsule Loaders

Capsule loaders have become essential in various industries. According to a recent industry report, businesses that utilize capsule loaders experience a productivity increase of up to 25%. This boost often stems from streamlined processes and reduced labor costs. Many companies report that with the automation of the loading process, employees can focus on quality control rather than labor-intensive tasks.

Another study highlighted that companies adopting capsule loaders achieve a faster output rate. Some facilities note an output increase of nearly 30% within the first year of implementation. It’s intriguing to see how investment in such technology pays off. Yet, companies must also reflect on their specific needs. Not every business environment is suited for a capsule loader. Sometimes, human intervention in loading can lead to improved flexibility and customization.

However, the initial investment can be significant. Businesses may hesitate due to costs and training requirements. Understanding these challenges is crucial. Some small businesses might find it overwhelming, causing them to overlook potential gains. By weighing the long-term benefits against upfront costs, decisions can become clearer.

Productivity Improvements with Capsule Loaders

This chart illustrates the significant increase in productivity percentages observed before and after the implementation of capsule loader machines in businesses. The data shows an improvement from 45% to 85%, highlighting the effectiveness of capsule loaders in enhancing operational efficiency.

Cost-Benefit Analysis: Capsule Loader Machines vs. Traditional Methods

When considering capsule loader machines, a cost-benefit analysis reveals significant advantages over traditional methods. For starters, capsule loaders streamline the filling process. They reduce manual labor, often cutting staffing costs. Automation leads to greater efficiency, which translates to lower operational expenses.

Traditional methods can be time-consuming and prone to errors. With manual filling, the chances of spills and mishaps increase. This can result in wasted product. Capsule loaders minimize this risk and enhance precision. The initial investment may seem high, but the long-term savings can be substantial. Businesses often find that the return on investment is worth it.

However, not all capsule loader machines are created equal. It's essential to assess specific business needs. Some machines may require extensive training, which could disrupt workflows. Also, maintenance costs can vary. Finding a machine that balances efficiency and affordability is crucial. Making an informed decision is vital for success.

Why Choose a Capsule Loader Machine for Your Business Needs? - Cost-Benefit Analysis: Capsule Loader Machines vs. Traditional Methods

| Criteria | Capsule Loader Machines | Traditional Methods |

|---|---|---|

| Initial Investment Cost | $15,000 - $30,000 | $5,000 - $10,000 |

| Labor Costs (Annual) | $12,000 | $24,000 |

| Production Rate (Capsules/Hour) | 3000 - 5000 | 500 - 1000 |

| Efficiency (% Utilization) | 90% | 70% |

| Maintenance Costs (Annual) | $500 | $1,200 |

| Space Requirement (sq ft) | 100 - 150 | 150 - 200 |

| Return on Investment (ROI) | 30% in Year 1 | 10% in Year 1 |

Real-World Applications of Capsule Loader Machines in Various Sectors

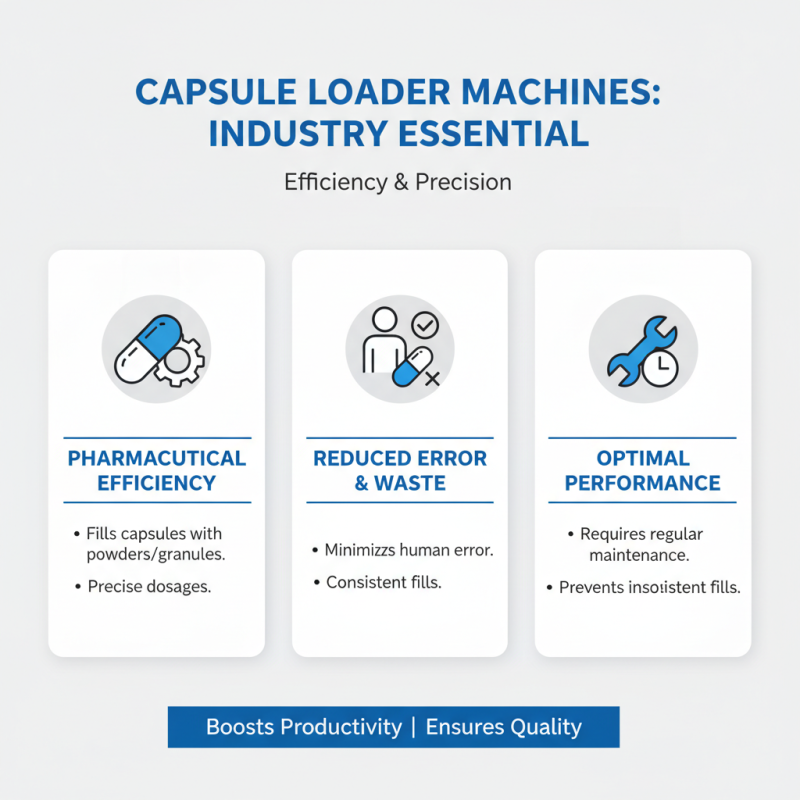

Capsule loader machines play a crucial role in various industries. In the pharmaceutical sector, they improve the efficiency of filling capsules with precise amounts of powders or granules. These machines can significantly reduce human error. Yet, they require regular maintenance to function optimally. Ignoring upkeep could lead to inconsistent fills and product waste.

In the nutraceutical industry, capsule loaders automate processes that would take hours manually. This saves time and resources. However, operators must be trained properly. Misunderstanding settings may lead to malfunction. By incorporating these machines, businesses can increase output and meet customer demands more effectively.

Food production also benefits from capsule loader technology. They package supplements, vitamins, and herbal products quickly. This quick turnaround is vital in a competitive market. However, scalability can be a challenge if the machine is not sized correctly for production needs. Balancing efficiency with appropriate capacity often requires careful planning.

Related Posts

-

The Ultimate Guide to Choosing the Right Capsule Loader Machine for Your Business Needs

-

Capsule Loader Machine Benefits and Working Process Explained?

-

Ultimate Checklist for Selecting the Right Capsule Loader Machine for Your Production Needs

-

Unveiling the Future: How Capsule Loader Machines Are Revolutionizing Pharmaceutical Production with 30% Efficiency Gains

-

Elevating Manufacturing Standards with the Best Capsule Loader Machine

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs