Blog

How to Choose the Best Natoli Tablet Press for Your Needs?

Choosing the right Natoli Tablet Press is crucial for pharmaceutical manufacturing. With a wide variety of options, making the right selection can significantly impact efficiency and product quality. According to a recent report by the International Journal of Pharmaceutical Manufacturing, around 70% of manufacturers struggle with selecting suitable equipment for their specific needs.

Dr. Sarah Thompson, a leading expert in tablet formulation, emphasizes, "The right press is essential to achieving consistent results in production." This statement underlines the importance of understanding both the technical specifications and the unique requirements of your production process. Each Natoli Tablet Press comes with different features that cater to various pharmaceutical applications.

A careful analysis of these features can lead to better productivity. It's not uncommon for companies to overlook details during selection. Such oversights can lead to inefficiencies and increased costs. Therefore, taking a step back and reflecting on your specific needs is imperative to finding the optimal Natoli Tablet Press for your operations.

Understanding Your Tablet Production Requirements

Understanding your tablet production requirements is crucial when choosing a tablet press. Start by assessing your production volume. Are you aiming for small batches or large-scale production? This decision impacts the type of press you will need. A high-speed press may be ideal for large outputs. But it might not be worth the investment for smaller production needs.

Consider the materials you will use. Different materials behave differently under pressure. Some may require specific tooling or adjustments. This can affect your choice. It is essential to ensure the press can handle your chosen materials effectively. Think about the tablet size and shape as well. Your requirements here will influence the dies and punches you'll need.

Lastly, evaluate the user interface and maintenance needs. A complex system may slow down your production. Easy maintenance is key for consistent output. Reflect on these aspects to determine if you have a clear understanding of your needs. Sometimes, it helps to consult with an expert. Staying flexible with your requirements can lead to better decision-making.

Tablet Production Requirements Analysis

Key Features to Consider in a Natoli Tablet Press

When selecting a tablet press, key features can make a significant difference. Understanding your production needs is essential. The size and capacity of the press play a crucial role. Smaller presses may suit limited production runs, while larger models handle higher capacities. Look for flexibility in tooling options. This allows you to produce various tablet shapes and sizes without hassle.

Another vital feature is the ease of operation. A user-friendly interface can streamline the process. Training operators becomes simpler when the controls are intuitive. Pay attention to maintenance needs too. Some machines may require frequent parts replacements, leading to downtime. Assess the availability of support and spare parts, as this impacts long-term efficiency.

Lastly, think about the machine's solidity. A robust design influences consistency in tablet formation. If the press feels flimsy, it's worth reconsidering. Security features matter as well. Safety protocols can prevent accidents during operation. Ensuring operator safety should never be overlooked. Look for balance in features and durability when making your decision.

Comparing Different Natoli Tablet Press Models

When comparing different tablet press models, several key factors come into play. The industry standard indicates that production efficiency and tablet quality are paramount. A report by the International Pharmaceutical Federation highlights that a well-designed tablet press can achieve up to 99% yield efficiency. This means that model selection can significantly impact manufacturing output.

Different models cater to various production needs. Some are designed for high-speed production while others excel in flexibility for smaller batches. For instance, a robust machine may handle thicker powders better but might struggle with more delicate formulations. A recent survey indicated that 40% of manufacturers report performance issues when switching formulations without adjusting their equipment. This often leads to unexpected downtime and increased costs.

Understanding these nuances can help prevent costly mistakes. Compact models might save space but may limit scalability. Conversely, larger machines offer more capabilities but can be an investment. It's crucial to assess operational demands and future growth. Making the right choice can directly influence efficiency, cost-effectiveness, and compliance with regulatory standards in an increasingly competitive market.

How to Choose the Best Natoli Tablet Press for Your Needs? - Comparing Different Natoli Tablet Press Models

| Model | Max Output (Tablets/hour) | Die Size (mm) | Punch Diameter (mm) | Features |

|---|---|---|---|---|

| Model A | 150,000 | 30 | 16 | Automatic feeder, High pressure |

| Model B | 200,000 | 25 | 13 | Multi-layer capability, Vibration control |

| Model C | 100,000 | 40 | 18 | Compact design, User-friendly interface |

Evaluating Cost and Budget for Your Tablet Press Purchase

When selecting a tablet press, cost is a crucial factor. Understand your budget clearly before making a decision. Consider the initial purchase price and ongoing maintenance costs. Many buyers overlook these ongoing expenses. Unexpected costs can arise, potentially causing financial strain.

Evaluate what features you truly need. High-end models offer advanced technologies, but they may exceed your budget. A basic model might suffice for smaller operations. However, be careful—cheap options can lead to more repairs. Think about the long-term impact on your resources.

Don’t forget to consider hidden costs. Installation, training, and possible upgrades can add up quickly. Set aside extra funds for these elements. Always compare prices and options thoroughly. This evaluation helps ensure you're making an informed decision that aligns with your financial situation. Seek advice but trust your instincts.

Maintenance and Support Options for Natoli Tablet Presses

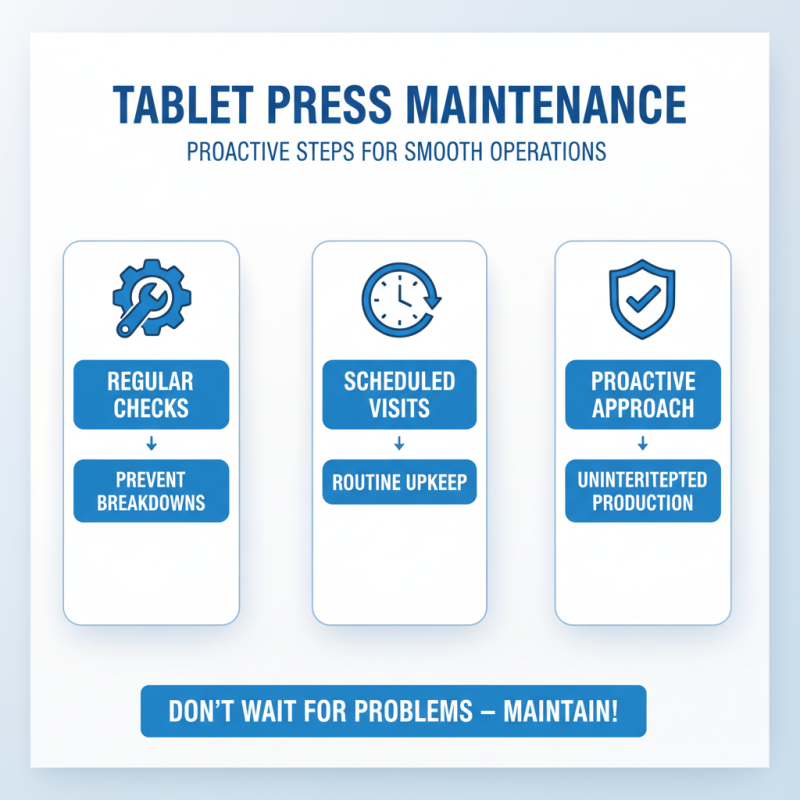

When considering a tablet press, maintenance is crucial. Regular checks can prevent unexpected breakdowns. You shouldn’t wait for a problem to arise. Schedule maintenance visits routinely. This proactive approach keeps operations smooth.

Support options are equally important. Technical support should be easy to access. You may encounter issues you’re unsure how to resolve. Quick responses can save time and resources. Training for personnel is also vital. Employees need to understand the machine fully. This reduces the risk of errors that can occur from misuse.

Remember, no system is perfect. Even the best machines can have hiccups. It's wise to have a solid support system in place. Reflect on past challenges with equipment. Learn from them to make informed decisions. An informed choice leads to better long-term results.

Related Posts

-

Mastering Natoli Tablet Press Techniques for Optimal Performance

-

Top 10 Natoli Tablet Press Benefits and Features to Know?

-

What is Natoli Tablet Press and How Does It Improve Tablet Production

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques

-

Why Choose Natoli Tablet Press for Your Pharmaceutical Manufacturing Needs

-

What is a Tablet Presser and How Does it Work?