Blog

2025 How to Choose the Best Capsule Loader Machine for Your Business

Choosing the right Capsule Loader Machine can significantly impact your business’s efficiency and productivity. Experts in the field emphasize its importance. Dr. Amanda Lee, a specialist in pharmaceutical machinery, states, "Selecting the right loader is crucial for optimal performance."

When evaluating different machines, consider your specific needs. The capacity, speed, and reliability of the Capsule Loader Machine all play vital roles. You might be tempted to prioritize cost. However, a cheaper option could lead to inefficiencies later on.

Moreover, think about maintenance and support. An unreliable machine can halt production unexpectedly. A robust loader requires less downtime. Researching user reviews and expert opinions can uncover insights. Making a thoughtful decision isn’t easy, but it’s important. Balancing quality and budget shapes long-term success.

Understanding the Importance of Capsule Loader Machines in Business

Capsule loader machines play a pivotal role in the pharmaceutical and nutraceutical industries. They automate the process of filling capsules, boosting efficiency and productivity. According to a recent industry report, the global capsule filling machine market is projected to reach USD 1.7 billion by 2025. This growth highlights the technology's significance in meeting increasing consumer demands.

In a business, efficiency translates directly into profit. Manual capsule filling is labor-intensive and time-consuming. This can lead to errors and inconsistencies. A well-chosen capsule loader can minimize these risks, ensuring uniform dosages and improved product quality. However, many businesses still struggle with machine selection. Poor choices can result in higher operational costs and wasted resources.

Not all machines are created equal. It is crucial to assess specific needs. Factors such as production volume and the type of capsules must be considered. Data from industry specialists suggest that nearly 40% of businesses fail to consider scalability. This oversight can impair future growth. Investing in the right capsule loader is therefore essential for long-term success.

Key Factors to Consider When Selecting a Capsule Loader Machine

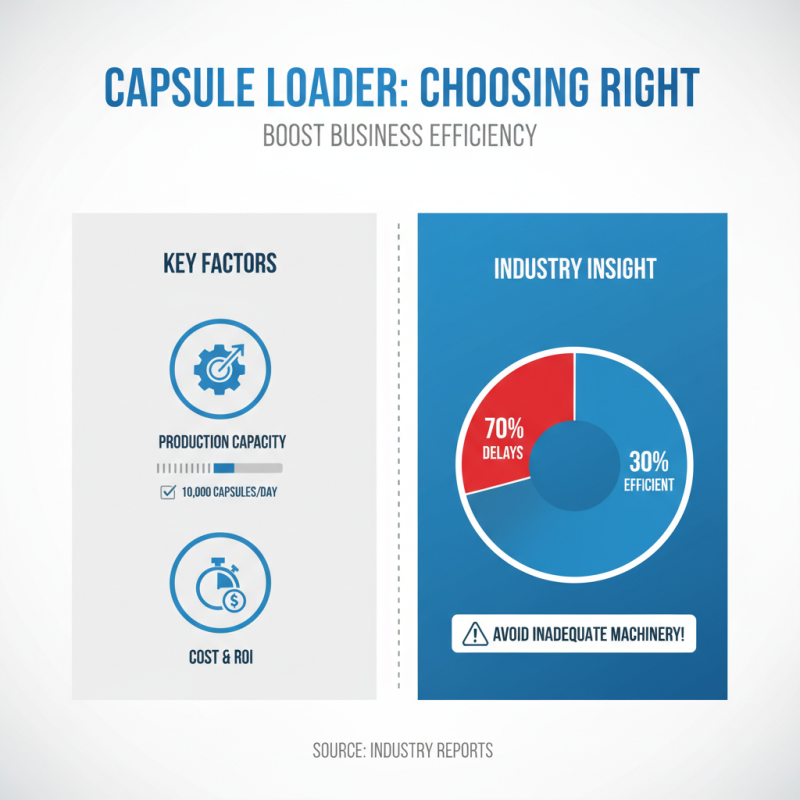

Choosing the right capsule loader machine is crucial for business efficiency. Several factors need your attention. Begin with production capacity. A machine should meet your output requirements. For instance, if your demand is 10,000 capsules daily, ensure the machine can handle that volume. According to industry reports, around 70% of businesses experience delays due to inadequate machinery.

Next, consider the machine's compatibility with your capsules. Sizes vary. Different formulations require different loading techniques. A mismatch can lead to wastage. Interestingly, research shows that nearly 30% of users overlook this factor, leading to operational inefficiencies.

Tip: Always consult with an expert. They can guide you based on your specific needs. This step can prevent costly mistakes. Additionally, examine the ease of maintenance. Regular upkeep is essential for long-term performance. Poor maintenance practices can reduce productivity by up to 25%. Don't ignore this aspect. Investing time in research can save you from potential pitfalls and enhance your operational success.

Comparing Different Types of Capsule Loader Machines Available

Choosing the right capsule loader machine for your business can be challenging. Different types of machines serve various needs. For example, manual loaders require hands-on operation. They are cost-effective but may not meet high-volume demands. On the other hand, semi-automatic machines can speed up the process. They reduce labor costs but still need some manual input.

Fully automatic capsule loaders are ideal for large-scale operations. They offer speed and efficiency, yet their investment can be significant. Consider your production needs. If you're starting small, a manual or semi-automatic option may suffice. Large businesses often benefit from automation. However, automation comes with maintenance costs that can't be ignored.

Evaluate the features before making a decision. Some machines come with advanced settings for different capsule sizes. Others may lack this flexibility, limiting your options. Reflect on your growth plans. A machine that fits today might not suit future needs. Also, consider the learning curve for staff. A complex machine might require extensive training, which can divert time and resources. Keep efficiency and usability in mind as you decide.

Evaluating the Manufacturer's Reputation and Support Services

When selecting a capsule loader machine, the manufacturer's reputation matters. A solid reputation often reflects years of reliable service. Look for reviews and testimonials. A company with positive feedback is likely trustworthy. Ask for references if possible. Many businesses share their experiences online. This can provide useful insights.

Support services are equally crucial. Does the manufacturer offer good customer support? Consider their response time. Are they available after purchasing? This can impact your production line. A reliable supplier will assist promptly when issues arise. Check if they provide training on the machine. This can make the transition smoother.

Lastly, picture your needs. Will the machine scale with your business? It’s essential to find a balance between quality and cost. A lower price might seem appealing, but it could cost more in repairs. Think critically about your choices. A reputable manufacturer will help guide you. Don’t rush the decision; it’s vital for your success.

2025 Capsule Loader Machine Evaluation Metrics

Cost-Effectiveness: Balancing Quality and Budget for Your Machine

Choosing a capsule loader machine requires careful consideration of cost-effectiveness. A significant part of successful business operations relies on balancing quality with budget. Investing in a high-quality machine may seem daunting, but cutting corners can lead to larger setbacks down the line. It’s essential to analyze your production volume and operational needs before making any decisions.

While exploring options, consider not just the purchase price but also maintenance costs. Some machines may attract you with a lower upfront price, but hidden costs can accumulate. A machine that is easy to clean and service may reduce downtime. Assess warranty offerings diligently. A strong warranty can save you from unexpected expenditures. However, read the fine print carefully.

Do not overlook the importance of scalability. Your business needs may evolve, and a cost-effective solution today may not serve its purpose tomorrow. If your production processing could double in a year, select a machine that accommodates growth. Remember, the cheapest option isn’t always the best choice. Reflect on your current and future needs to ensure a wise investment.

Related Posts

-

Elevating Manufacturing Standards with the Best Capsule Loader Machine

-

Top Strategies for Optimizing Your Capsule Loader Machine Procurement Process

-

How to Choose the Right Capsule Loader Machine for Your Business Needs

-

Ultimate Guide to Efficient Capsule Loader Machine Solutions for Your Production Needs

-

Common Issues Faced by Businesses When Choosing Capsule Packaging Machines

-

Ultimate Checklist for Selecting the Right Capsule Loader Machine for Your Production Needs