Blog

Why Choose a Powder Pulverizer for Your Processing Needs?

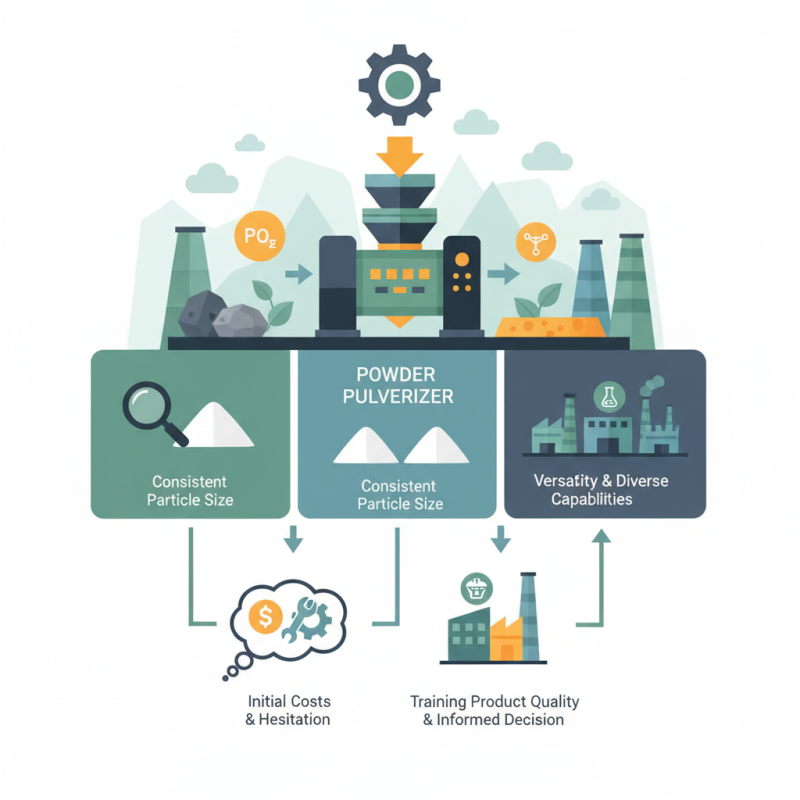

In the evolving landscape of industrial processing, the need for efficiency is paramount. Experts like Dr. Jane Thompson, a leading figure in material processing, emphasize, "A Powder Pulverizer is crucial for achieving consistent particle size." This statement highlights the significance of technology in streamlining production lines.

The Powder Pulverizer stands out for its versatility. It can handle various materials, providing tailored solutions for diverse industries. Many businesses have benefitted from its ability to reduce particle size uniformly, enhancing product quality. However, some companies still hesitate, unsure of the transition.

Investing in a Powder Pulverizer is a commitment, yet it may reveal unforeseen challenges. The initial costs can be daunting, and proper training is essential for operators. Understanding the capabilities and limitations is vital for success. Recognizing these factors can lead to a more informed decision.

Understanding Powder Pulverizers and Their Functionality

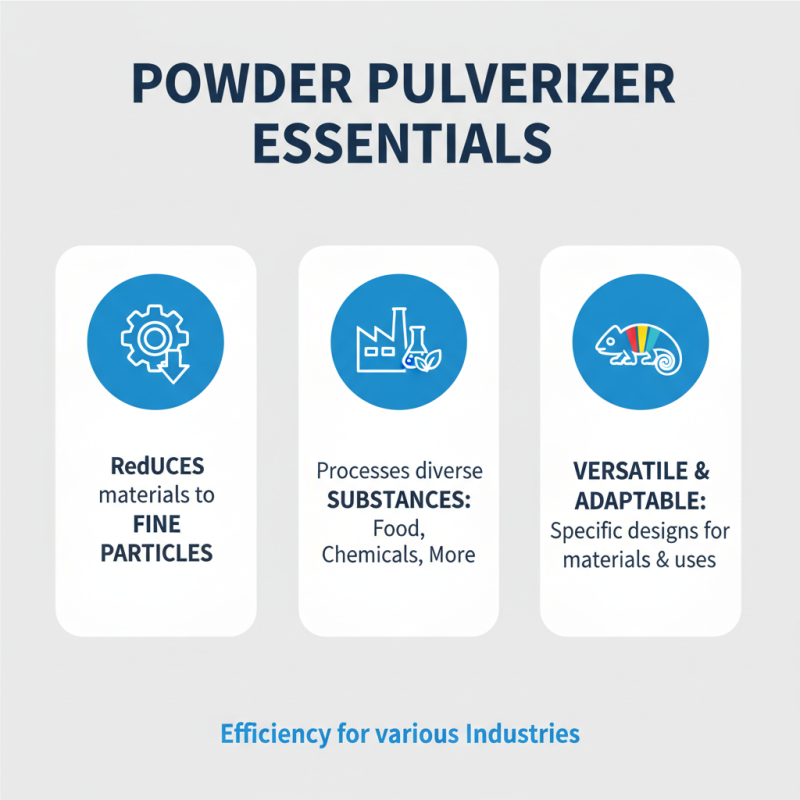

A powder pulverizer is essential in many industries. It efficiently reduces materials to fine particles. These machines are known for their ability to process various substances, from food ingredients to chemicals. Their versatility is appealing. Specific designs cater to different materials and applications.

Understanding how these machines function is crucial. A powerful motor drives the pulverizing process, generating high speeds. This leads to rapid particle size reduction. The result is a uniform powder that can enhance product quality. Some pulverizers allow adjustments in size settings. This flexibility helps meet specific processing needs.

However, challenges exist. Users must ensure that materials are suitable for pulverization. Improper use may lead to poor quality or equipment damage. Regular maintenance is also essential for optimal performance. Dust management is important in facilities. It is easy to overlook these details, yet they can significantly impact results.

Benefits of Using a Powder Pulverizer in Material Processing

Using a powder pulverizer offers distinct advantages for material processing. Firstly, these machines ensure a consistent particle size. When materials are uniformly sized, they perform better in various applications. This consistency can lead to higher quality final products. Moreover, specific industries often require fine particle distributions, which these pulverizers can accomplish with precision.

Efficiency is another key benefit. A powder pulverizer can significantly reduce processing time. Traditional methods oftentimes produce inconsistent results. This inconsistency can waste time and resources. By employing a pulverizer, you streamline your workflow. It reduces manual intervention, minimizing human error.

However, it’s important to consider potential drawbacks. Maintenance can be demanding. Regular checks are necessary to keep machinery running smoothly. Operators must also be trained properly. Misuse can lead to inefficiency or damage. Also, initial investment costs may be high. Balancing these factors is crucial. A well-planned approach can optimize performance and improve processing outcomes significantly.

Benefits of Using a Powder Pulverizer in Material Processing

Applications of Powder Pulverizers Across Various Industries

Powder pulverizers are essential tools in various industries. They effectively reduce materials to fine powders. This process is crucial in sectors like food processing, pharmaceuticals, and chemicals. For instance, in food industries, spices and grains are often ground into fine powders for better flavor and texture. These pulverizers ensure uniformity and consistency, enhancing product quality.

In the pharmaceutical industry, powdered drugs must meet stringent standards. Precise pulverization is needed to create formulations. This improves bioavailability and absorption rates in the human body. Additionally, in the chemical sector, raw materials are pulverized to ensure better mixing and reactions. Yet, using pulverizers comes with challenges. Adjusting the settings for different materials can take time. Mishandling can lead to waste and contamination. Careful monitoring is necessary to avoid such pitfalls.

Ultimately, while powder pulverizers serve diverse applications, their effective use requires constant reflection. Understanding each material’s unique properties is vital. It’s a balance of technique and knowledge that leads to successful processing outcomes. Each industry presents opportunities for improvement and innovation. Always strive for better practices while using these machines.

Key Considerations When Selecting a Powder Pulverizer

Choosing the right powder pulverizer involves careful consideration. Different applications require different types of equipment. It's essential to evaluate the material being processed. Some materials are more abrasive than others. This can impact the design and durability of the pulverizer.

Another important factor is the desired particle size. Various applications call for different powder fineness. A good pulverizer should offer adjustable settings. This flexibility can enhance efficiency. However, not all machines provide this feature. Users should research how well each pulverizer meets their specific needs.

Power consumption is another key consideration. Efficient machines save on energy costs. Yet, some models can consume excessive energy. It’s wise to weigh the energy benefits against performance. Noise levels can also be a concern. Some pulverizers operate loudly, affecting workplace comfort. Balancing these factors can lead to better processing decisions.

Why Choose a Powder Pulverizer for Your Processing Needs?

| Aspect | Consideration | Importance |

|---|---|---|

| Particle Size | Determine the required particle size based on application needs. | High |

| Material Type | Identify compatibility with various materials (hardness, abrasiveness). | Medium |

| Production Capacity | Assess desired throughput and operational efficiency. | High |

| Energy Consumption | Evaluate energy efficiency to reduce operational costs. | High |

| Maintenance Requirements | Consider ease of maintenance and availability of parts. | Medium |

| Cost | Analyze upfront costs versus long-term operational costs. | High |

| Safety Features | Evaluate safety measures in design to protect operators. | High |

| Customization Options | Determine if customization is available to meet specific needs. | Medium |

Maintenance Tips for Ensuring Longevity of Powder Pulverizers

Maintaining a powder pulverizer is crucial for its efficiency and lifespan. Regular inspections are a must. Check for wear in moving parts. A study by the American Institute of Mechanical Engineers highlights that 50% of equipment failures result from improper maintenance. Skipping these checks could lead to costly downtime.

Cleaning is another key aspect. Ensure that all parts are free of residue. Even small amounts can affect performance. The industry suggests a thorough clean after every use. Neglecting this can lead to contamination and inconsistent product quality. Data shows that cleanliness can improve product consistency by up to 30%.

Lubrication should not be overlooked. Use appropriate lubricants to prevent friction. Inadequate lubrication can double mechanical wear. Adjust maintenance schedules based on operating conditions. Harsh environments necessitate more frequent checks. Ignoring these factors could shorten the machine's life significantly.

Related Posts

-

How the Best Powder Pulverizer Transforms Food Processing: Industry Case Studies and Insights

-

Ultimate Guide to Choosing the Best Powder Pulverizer for Your Industrial Needs

-

How to Master the Art of Powder Pulverization for Optimal Results

-

How to Maximize Efficiency in Your Powder Pulverizer Operations for Optimal Product Output

-

What is a Capsules Filling Machine? Benefits, Types, and How It Works

-

Top 5 Oral Dispersible Tablets for 2025 That You Need to Know About