Blog

What is a Capsules Filling Machine? Benefits, Types, and How It Works

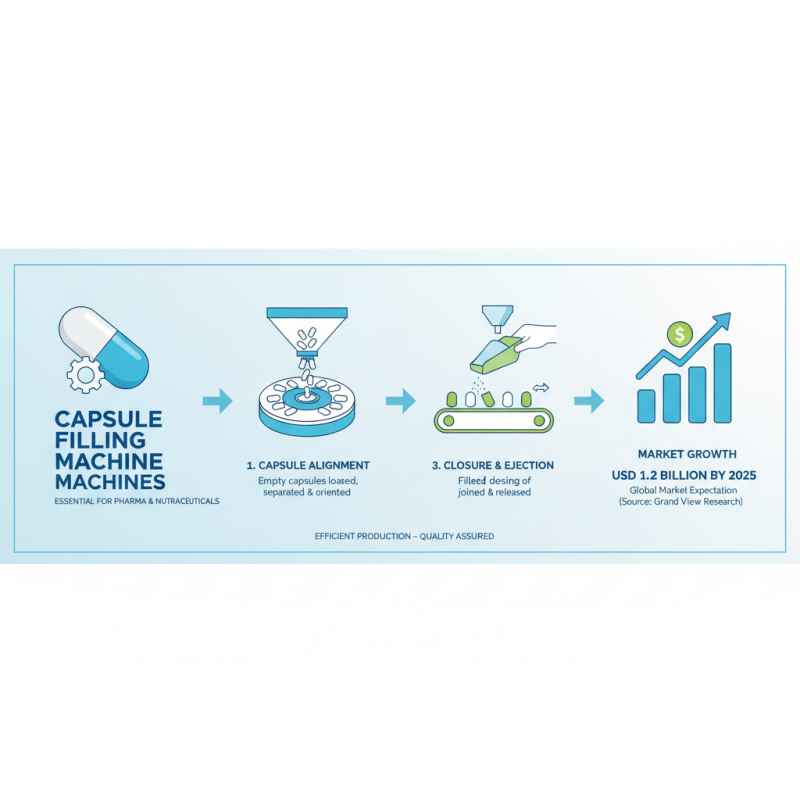

In the fast-evolving pharmaceutical and nutraceutical industries, the demand for efficiency and precision in drug formulation has propelled the adoption of advanced technologies. A Capsules Filling Machine stands at the forefront of this transformation, streamlining the process of encapsulating powder, pellets, or liquids into dosage forms for better consumer compliance. According to a report by MarketsandMarkets, the global market for capsule filling machines is projected to reach USD 1.2 billion by 2026, highlighting the increasing need for automation in pharmaceutical production.

Industry expert Dr. Emily Carter, a leading researcher at the Institute of Pharmaceutical Technology, emphasizes the significance of these machines, stating, "The Capsules Filling Machine is not just about filling; it's about ensuring consistency, quality, and efficiency in the drug manufacturing process." This underscores the critical role that these machines play in maintaining industry standards while also adapting to the growing complexities of modern formulation demands. As manufacturers seek to optimize their production capabilities, understanding the benefits, types, and operational mechanics of capsules filling machines becomes essential for staying competitive in the market.

What is a Capsule Filling Machine?

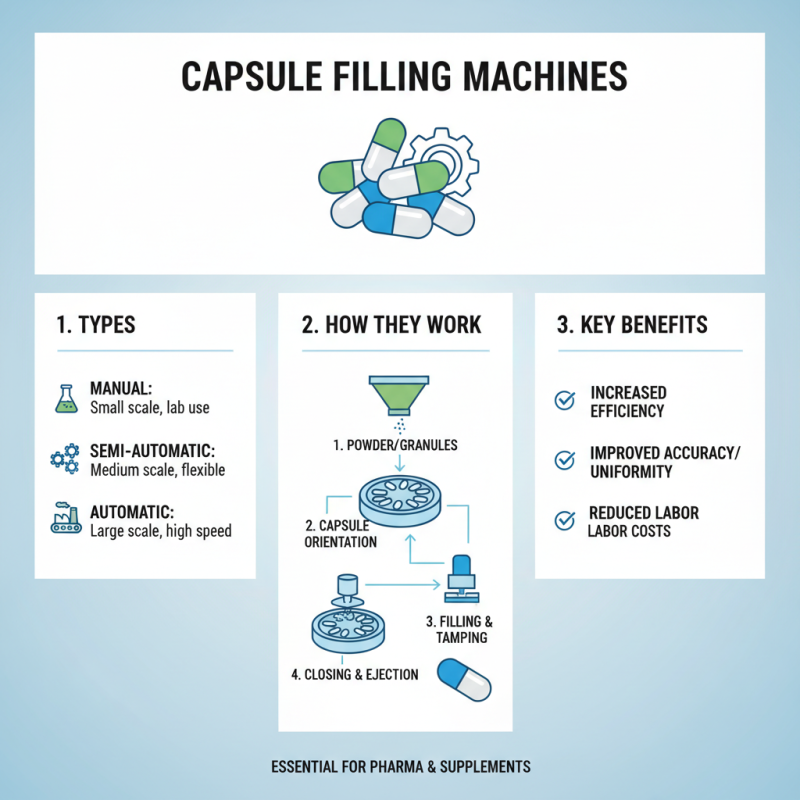

A capsule filling machine is a specialized device used in the pharmaceutical and nutritional industries to automate the process of filling empty capsules with desired substances such as powders, granules, or pellets. These machines streamline the production process by increasing efficiency, ensuring consistency, and reducing manual labor. Capsule filling machines are essential for those producing dietary supplements, herbal medicines, and various pharmaceutical products.

The working principle of a capsule filling machine typically involves several key steps. First, empty capsules are separated and aligned for filling. Next, the machine measures and dispenses the specific amount of substance into each capsule. Various machine types exist, ranging from manual to fully automated systems, each designed to cater to different production volumes and requirements. Automated machines often utilize advanced technology for precise filling, ensuring that each capsule is packed uniformly, while manual machines may require a hands-on approach, making them suitable for smaller operations. Overall, capsule filling machines play a crucial role in enhancing the efficiency and quality of capsule production in various sectors.

Capsule Filling Machine Usage Statistics

Key Benefits of Using Capsule Filling Machines

Capsule filling machines have become increasingly popular in various industries due to their numerous key benefits. One of the primary advantages of using a capsule filling machine is the enhancement of efficiency in the production process.

These machines allow for quick and precise filling of capsules, significantly reducing the time spent compared to manual methods. As a result, manufacturers can boost their output and meet higher demand without compromising on quality.

Another notable benefit is the versatility capsule filling machines offer. They can handle different types of formulations, ranging from powders to pellets, accommodating a wide range of products for dietary supplements, pharmaceuticals, and nutraceuticals. This flexibility makes it easier for businesses to adapt to changing market trends and consumer preferences, allowing for a more agile response to demands.

Tips: When considering a capsule filling machine, it’s crucial to assess the scale of your production needs. For smaller batches, semi-automatic machines may suffice, while larger operations might benefit from fully automatic models. Additionally, pay attention to the cleaning and maintenance requirements of the machine to ensure long-term efficiency and hygiene in your production line. Investing in training for your staff on how to operate the machine can also lead to optimized performance and reduced error rates.

Different Types of Capsule Filling Machines Explained

Capsule filling machines are essential equipment used in the pharmaceutical and supplement industries, designed to automate the process of filling capsules with powders or granules. There are several types of capsule filling machines, each catering to different production scales and requirements.

Manual capsule filling machines are ideal for small-scale production. These machines allow operators to fill capsules by hand, making them suitable for herbalists or small businesses focusing on custom formulations. On the other hand, semi-automatic machines enhance efficiency by automating parts of the process while still requiring operator oversight. These machines are often employed in medium-scale operations, providing a balance between efficiency and control.

For large-scale production, fully automatic capsule filling machines are the go-to choice. These robust machines can handle high volumes, increasing productivity while minimizing human error. They are equipped with advanced technology to ensure precision in filling and reliable output.

**Tip:** When choosing a capsule filling machine, consider the scale of production and the specific features that meet your operational needs, such as ease of cleaning and maintenance. Always ensure the machine complies with industry standards to maintain product quality and safety.

How Capsule Filling Machines Operate: A Step-by-Step Guide

Capsule filling machines play a crucial role in the pharmaceutical and nutraceutical industries, enabling the efficient production of encapsulated products. These machines typically operate through a series of precise steps, ensuring quality and consistency in every batch. Initially, the machine's hopper is filled with empty capsules, which are then separated and aligned. This is followed by the filling process, where the selected powder or granule mixture is accurately dosed into each capsule half. According to a market research report by Grand View Research, the global capsule filling machine market is expected to reach USD 1.2 billion by 2025, underscoring the growing demand for efficient manufacturing processes in the industry.

Once filled, the capsules are sealed, often through a combination of mechanical pressure and heat, which ensures that the product remains intact during storage and distribution. After sealing, the capsules undergo quality checks to maintain high standards of safety and efficacy. The entire operation is typically automated, which not only speeds up production but also reduces the potential for human error. A report published by Market Research Future highlights that automation in capsule filling can enhance production efficiency by up to 30%, illustrating the importance of these machines in modern manufacturing. This step-by-step operation ensures that businesses can meet increasing consumer demands while maintaining product integrity.

Applications of Capsule Filling Machines in Various Industries

Capsule filling machines have a wide range of applications across various industries, primarily due to their efficiency and versatility in packaging. In the pharmaceutical sector, these machines are indispensable for producing accurate and consistent dosages of medications in capsule form. This not only ensures patient safety but also improves the overall effectiveness of drug delivery by providing precise dosages tailored to individual needs. Moreover, the ability to fill capsules with both powders and pellets allows for innovative formulations, catering to different therapeutic requirements and enhancing patient compliance.

In the nutraceutical and dietary supplement industries, capsule filling machines facilitate the production of vitamins, minerals, and herbal supplements in capsule form, which are increasingly popular among health-conscious consumers. These machines allow for the quick and efficient filling of various types of capsules, accommodating diverse formulations—from simple powders to complex blend mixtures. Additionally, the cosmetic industry has also recognized the benefits of capsule technology, using filling machines to create single-dose applications of skincare products or supplements, enhancing convenience and ensuring product integrity. The flexibility and adaptability of capsule filling machines make them a pivotal element in advancing product development across multiple sectors.

What is a Capsules Filling Machine? Benefits, Types, and How It Works - Applications of Capsule Filling Machines in Various Industries

| Dimension | Description |

|---|---|

| Machine Type | Manual, Semi-Automatic, Fully Automatic |

| Filling Capacity | 1,000 to 100,000 capsules per hour |

| Materials Used | Gelatin, HPMC (Hydroxypropyl Methylcellulose) |

| Main Applications | Pharmaceutical, Nutraceutical, Food, Cosmetics |

| Key Benefits | Efficiency, Precision, Versatility, Cost-Effectiveness |

| Commonly Used In | Pharmaceutical manufacturing plants, dietary supplement manufacturers |

| Working Principle | Filling powder or liquid into capsule shells using precise measurements |

| Regulatory Standards | GMP (Good Manufacturing Practices), ISO Standards |

Related Posts

-

Revolutionizing Your Production Line: The Ultimate Guide to Capsules Filling Machines

-

How to Choose the Right Capsules Filling Machine for Your Production Needs

-

Top Capsules Filling Machines of 2025 for Efficient Pharmaceutical Production

-

Common Issues Faced by Businesses When Choosing Capsule Packaging Machines

-

7 Best Capsule Packaging Machines for Enhanced Efficiency in 2023

-

How to Optimize Tablet Presser Efficiency with Data Driven Insights on Compression Techniques