Blog

Capsule Loader Machine Benefits and Working Process Explained?

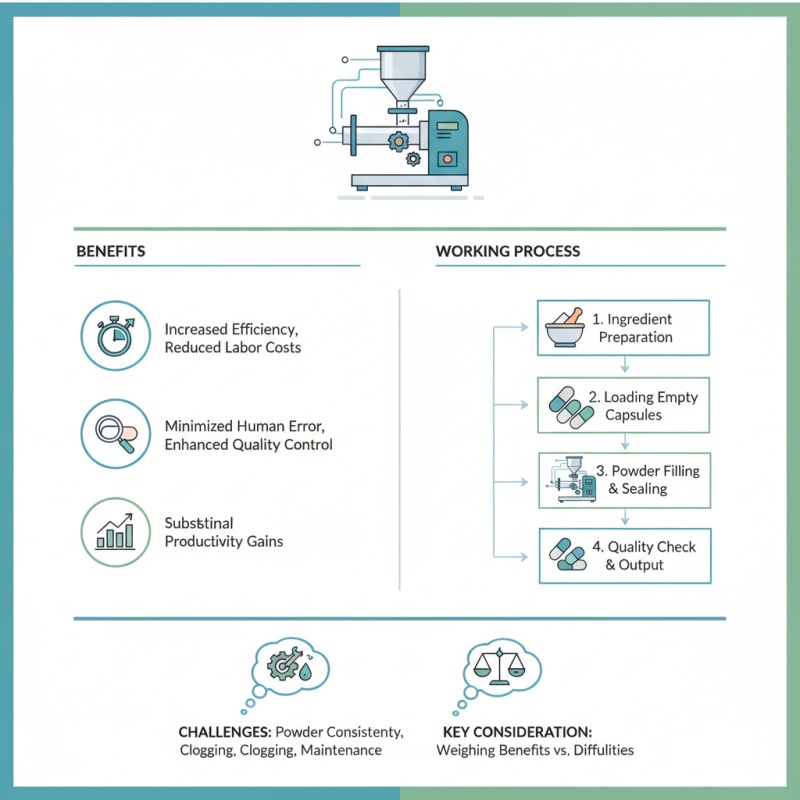

The Capsule Loader Machine is a vital tool in the pharmaceutical and nutraceutical industries. It greatly enhances the efficiency of encapsulation processes. By automating the loading of powder into capsules, this machine reduces labor costs and minimizes human error.

Understanding its working process is crucial for manufacturers. It involves several stages, from key ingredient preparation to filling empty capsules. Each phase demands precision and care. The automation simplifies quality control, but challenges can arise. Sometimes, there can be issues with powder consistency or clogging. Regular maintenance is essential to ensure optimal performance.

Investing in a Capsule Loader Machine can lead to substantial productivity gains. It is important to weigh the benefits against potential operational difficulties. Reflecting on the overall effectiveness of this equipment is key for any business.

Benefits of Using Capsule Loader Machines in Pharmaceutical Manufacturing

Capsule loader machines have revolutionized pharmaceutical manufacturing. They provide speed, precision, and efficiency to the filling process. In a competitive industry, these machines help boost productivity. According to a recent industry report, automation in manufacturing has led to a 30% increase in output rates. This significant enhancement results from the accuracy and reduced manual labor associated with capsule loaders.

Using capsule loader machines eliminates many human errors. This is crucial for maintaining quality control standards. The risk of contamination is also lower because machines handle the capsules. Many manufacturers have noticed a drop in batch failures by up to 25%. Enhanced reliability opens the door to more consistent production cycles.

**Tip:** Regular maintenance is vital. Even advanced machines require checking to ensure smooth operation and longevity. Take time for routine cleaning and calibrations. This can prevent major breakdowns and costly delays.

Cost savings are another compelling aspect. Automated systems reduce labor costs significantly. However, some techniques could still face challenges. Old machinery might lag in efficiency and increase operational costs over time. Continuous improvement is essential for staying ahead in the market.

Benefits of Using Capsule Loader Machines in Pharmaceutical Manufacturing

Overview of the Working Process of Capsule Loader Machines

Capsule loader machines play a crucial role in the pharmaceutical and nutraceutical industries. They automate the process of filling capsules with powders or granules. This leads to increased efficiency in production. Understanding their working process helps users maximize their benefits.

The working process begins with the selection of empty capsules. These capsules are then placed in a tray. The machine often uses a vibrating mechanism to ensure they are correctly aligned. Next, the machine fills each capsule with the desired product. This step requires precision. Any mismatch can lead to inconsistent dosing. Once filled, the capsules are ejected, ready for sealing or packaging.

Incorporating a capsule loader machine can seem straightforward. However, not all processes run perfectly. Issues such as blockages or incorrect fill weights can occur. Regular maintenance is essential. Observing the machine's operations can help identify potential problems early. Analyzing the filling process may reveal areas needing improvement. This approach encourages continuous refinement in capsule production.

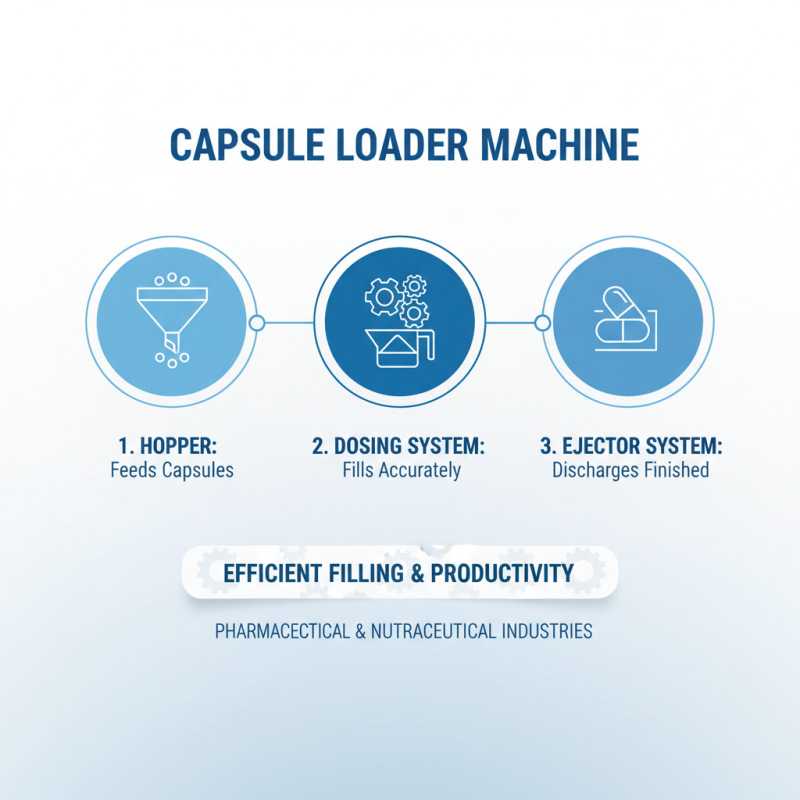

Key Components of Capsule Loader Machines and Their Functions

Capsule loader machines are integral to the pharmaceutical and nutraceutical industries. These machines ensure efficient capsule filling, improving productivity. The main components include the hopper, dosing system, and ejector system. Each part plays a crucial role in the process.

The hopper holds the capsule shells and the powder or pellets. It's designed to maintain a steady flow, crucial for uniform filling. The dosing system precisely measures the required amount of product. This accuracy minimizes waste and ensures high-quality output. Additionally, the ejector system safely releases filled capsules, maintaining a brisk operation.

Reports indicate that the global capsule filling machine market is projected to grow significantly. It is expected to reach USD 874 million by 2027. As demand rises, manufacturers must consider technology improvements. However, issues like machine maintenance and operator training remain challenges. Attention to these details is essential to maximize the benefits of capsule loader machines.

Industry Standards and Regulatory Compliance for Capsule Loading

Capsule loading machines play a crucial role in the pharmaceutical and nutraceutical industries. They must comply with industry standards and regulatory requirements. These regulations ensure the safety, efficacy, and quality of the products. Compliance involves strict guidelines on manufacturing processes, equipment maintenance, and employee training.

Accurate dosing is vital. Each capsule must contain the correct amount of active ingredients. Regular audits and checks can help maintain these standards. It’s important to document everything meticulously. This not only adheres to regulations but also promotes transparency within the organization.

Tips: Always keep training up-to-date. Ensure all staff members are familiar with current regulations. Conduct regular internal audits to identify areas for improvement. Remember, constantly improving processes can lead to better compliance and product quality. Continuous reflection on operations may unveil issues that need addressing.

Capsule Loader Machine Benefits and Working Process Explained

| Feature | Description | Benefits |

|---|---|---|

| High Throughput | Can load large volumes of capsules in a short period. | Increases production efficiency and reduces operational costs. |

| Precision Loading | Ensures accurate dosage per capsule without spillage. | Enhances product quality and compliance with regulations. |

| User-Friendly Interface | Equipped with intuitive controls for ease of use. | Reduces training time for operators and minimizes errors. |

| Compliance with Standards | Meets necessary industry standards and regulatory compliance. | Ensures safety and quality assurance in production. |

| Versatility | Can handle different capsule sizes and types. | Adaptable to various production needs, enhancing flexibility. |

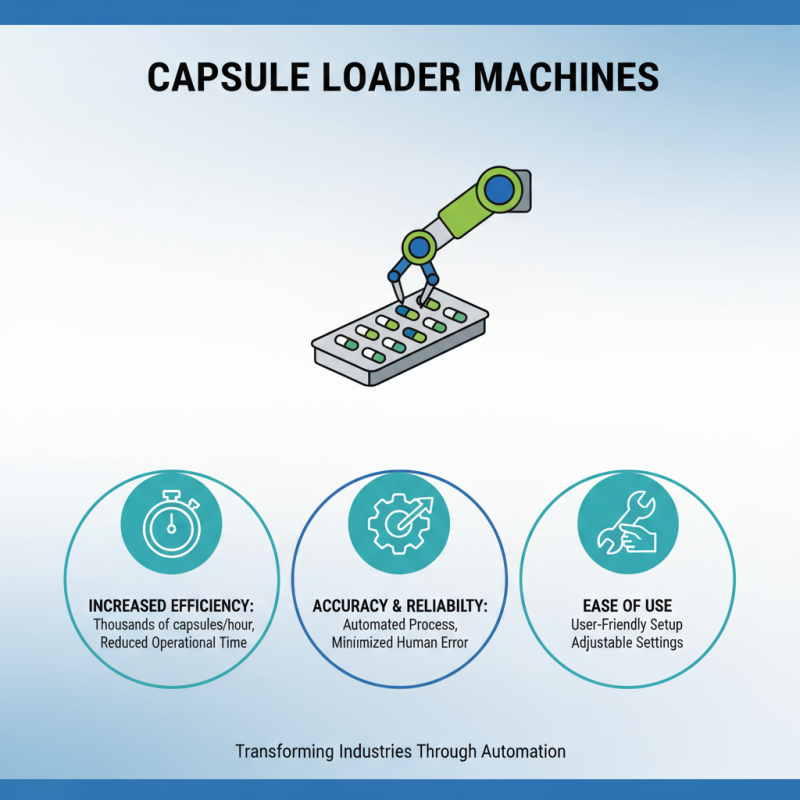

Efficiency Metrics: Speed and Accuracy of Capsule Loader Machines

Capsule loader machines have transformed various industries by enhancing efficiency metrics. These machines are designed for speed and accuracy in filling capsules. They automate the process, which minimizes human error. An efficient machine can fill thousands of capsules per hour, drastically reducing operational time. The setup is user-friendly, allowing operators to adjust settings easily during production runs.

Accuracy is equally important. A well-calibrated capsule loader ensures that each capsule is filled to the specified weight. This precision impacts product quality. Variations in fill weight can lead to issues with potency and customer satisfaction. Some machines, however, may struggle with certain powders, leading to inconsistencies. Operators often need to test different settings to find the sweet spot for efficiency and accuracy.

Maintenance cannot be overlooked. Regular checks are essential to keep machines running smoothly. Dust and debris can affect performance, leading to slowdowns. Operators must constantly monitor output and adjust parameters accordingly. This ongoing process of refinement highlights the importance of balancing speed with quality control. It's crucial to strike this balance to maintain production goals while meeting industry standards.

Related Posts

-

The Ultimate Guide to Choosing the Right Capsule Loader Machine for Your Business Needs

-

Ultimate Checklist for Selecting the Right Capsule Loader Machine for Your Production Needs

-

Unveiling the Future: How Capsule Loader Machines Are Revolutionizing Pharmaceutical Production with 30% Efficiency Gains

-

2025 How to Choose the Best Capsule Loader Machine for Your Business

-

Elevating Manufacturing Standards with the Best Capsule Loader Machine

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs