Blog

Best 10 Capsule Packaging Machines for Efficient Production?

In the fast-paced world of manufacturing, efficiency is key. A Capsule Packaging Machine plays a crucial role in this process. It streamlines production, reducing waste and saving time. Choosing the right machine can boost your operational workflow significantly. There are many models available, each with unique features.

This guide will explore the ten best capsule packaging machines on the market. These machines vary in capacity, design, and cost. Some are compact, perfect for small businesses. Others are larger, designed for high-volume production. It’s essential to consider your specific needs.

Not all machines are perfect. Some might not be user-friendly, requiring additional training. Others may have maintenance issues that arise unexpectedly. It’s vital to weigh these factors when making a decision. With careful consideration, you can find the right capsule packaging machine for your production needs.

Best 10 Capsule Packaging Machines: An Overview of Efficiency Metrics

The demand for capsule packaging machines has surged, especially in the pharmaceutical and nutraceutical industries. Efficiency metrics drive the choice of these machines, significantly impacting production rates and costs. According to industry reports, the average output of a modern capsule machine can exceed 100,000 capsules per hour. Innovations in technology have led to machines that offer superior accuracy and reduced waste, with many models achieving over 98% filling accuracy.

Efficiency metrics include not only speed but also energy consumption and maintenance needs. A machine that operates at high speed but requires constant downtime for maintenance can negate productivity gains. Data suggests that systems designed with user-friendly interfaces and quick changeovers can improve operational efficiency by up to 30%. This demonstrates the importance of considering total operational costs instead of focusing solely on the initial investment.

Tips: Evaluate the scalability of your chosen machine to future-proof your production line. Consider conducting a time and motion study for your current process. You may find chances for improvement that were previously overlooked. Balancing speed and reliability is crucial; sometimes, slower machines perform better in the long term.

Best 10 Capsule Packaging Machines for Efficient Production

| Machine Model | Production Speed (Capsules/min) | Filling Accuracy (%) | Power Consumption (kW) | Dimensions (L x W x H) mm |

|---|---|---|---|---|

| Model A | 300 | 99.5 | 5.5 | 1200 x 800 x 1800 |

| Model B | 250 | 98.0 | 4.0 | 1100 x 750 x 1700 |

| Model C | 400 | 99.0 | 6.0 | 1300 x 900 x 1900 |

| Model D | 350 | 97.5 | 5.0 | 1250 x 800 x 1850 |

| Model E | 280 | 99.8 | 4.5 | 1150 x 760 x 1750 |

Key Features to Consider in Capsule Packaging Machines for High Output

When selecting a capsule packaging machine, several key features greatly influence production efficiency. Speed is crucial. Machines with higher output rates can significantly decrease bottlenecks in packaging processes. Look for models that offer adjustable speeds to cater to different production needs. This flexibility can enhance overall efficiency.

Another vital aspect is the accuracy of filling. Machines should ensure precise dosage to minimize waste. Consider those that allow easy calibration. This can save time during setup. Maintenance is also essential. Opt for machines that are easy to clean and maintain, as this reduces downtime.

User-friendly interfaces make a big difference too. Machines with intuitive controls enable quicker training for operators. Check for features like touchscreen displays. Nonetheless, not every machine will perfectly meet expectations. Some may lack certain functionalities, while others could have higher operational costs. Reflecting on these aspects can help identify the right fit for your production line.

Production Efficiency of Capsule Packaging Machines

Comparative Analysis of Leading Brands in Capsule Packaging Technology

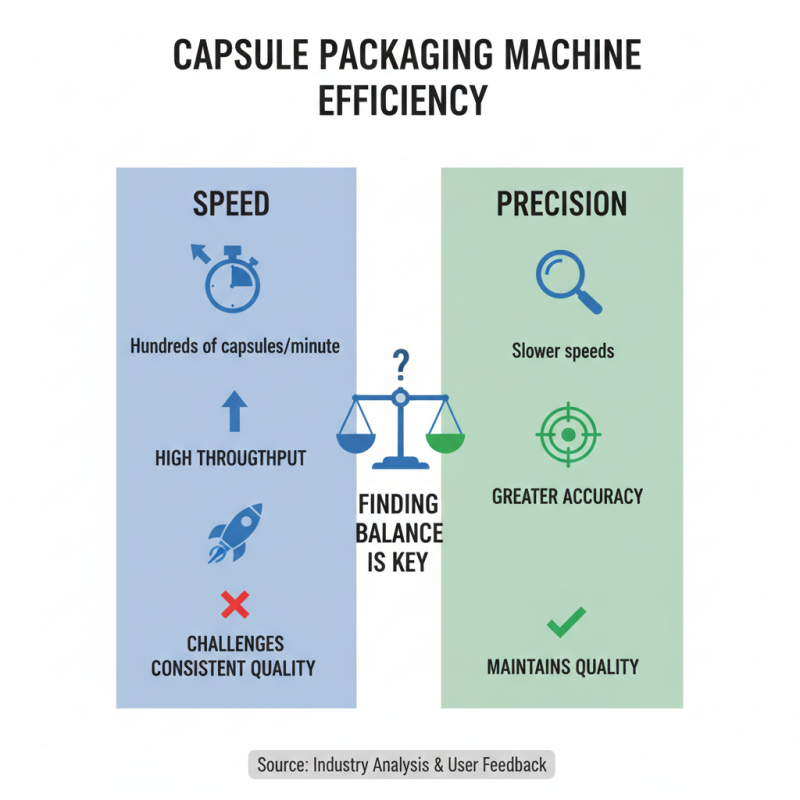

When evaluating capsule packaging machines, efficiency is key. Various brands offer machines with different speeds and capacities. Some machines pack hundreds of capsules per minute. Others might be slower but provide greater accuracy. Achieving the right balance between speed and precision is difficult. Many users have noted challenges in maintaining consistent quality during high-speed runs.

An important aspect is usability. Some machines have user-friendly interfaces, making training easier. However, others may require significant operator skill to function properly. This can lead to inefficiencies if staff members struggle with complex setups. Regular maintenance is another critical area. Neglecting upkeep can quickly hamper production speed and increase downtime.

Energy consumption is also a concern. Many machines advertise energy efficiency, but real-world performance often falls short. Some systems consume more power than expected during operations. Ultimately, brands vary widely in features and performance. Users should consider which aspects matter most for their production needs. Exploring customer reviews can provide insights into real-life experiences and potential pitfalls.

Impact of Capsule Packaging Efficiency on Pharmaceutical Production

The efficiency of capsule packaging significantly influences pharmaceutical production. Studies show that operational efficiency could improve by up to 30% with better packaging systems. A streamlined process reduces waste and lowers labor costs. In 2022, a report indicated that inefficient packaging accounted for nearly 20% of production delays in pharmaceutical plants. These delays can result in missing market opportunities.

Investing in modern capsule packaging machines not only enhances speed but also ensures accuracy. According to a recent industry analysis, 85% of pharmaceutical manufacturers saw reduced error rates with advanced equipment. However, the initial costs can be daunting. Many companies hesitate due to budget constraints. This reluctance can hinder their production capacity and efficiency in the long run.

Moreover, as demand for pharmaceuticals grows, so does the pressure on manufacturers. In 2023, projections estimate that the global demand for capsule packaging will rise by 15%. Companies must reconsider their packaging strategies to adapt to market changes. Balancing cost and efficiency is a complex challenge. Finding the right packaging solution is critical for staying competitive in an evolving sector.

Future Trends in Capsule Packaging Machines: Automation and Sustainability

The capsule packaging machine industry is shifting towards greater sustainability and automation. Recent reports indicate that the global market for capsule machines is projected to grow by 8.5% annually between 2021 and 2028. Companies are increasingly adopting automated systems. These systems enhance production efficiency while reducing labor costs, a significant factor for manufacturers.

Incorporating sustainable materials is becoming vital. Many companies are exploring biodegradable materials for capsule packaging. These innovations can reduce environmental impact. However, transitioning to sustainable solutions may present challenges, such as material sourcing and cost. It's essential for businesses to assess their needs carefully before making changes.

Tips:

- Consider the total cost of ownership when investing in new machines.

- Check the availability of sustainable materials for your packaging needs.

- Small adjustments can lead to a more eco-friendly operation.

- Balancing automation and sustainability requires thoughtful planning.

- Not all solutions fit every production line. Understand your operational limitations and long-term goals.

Related Posts

-

The Future of Capsule Packaging Machines in Sustainable Manufacturing

-

Elevating Manufacturing Standards with the Best Capsule Loader Machine

-

Ultimate Guide to Choosing the Best Capsule Filling Plate for Your Needs

-

Ultimate Guide to Efficient Capsule Loader Machine Solutions for Your Production Needs

-

Top Strategies for Optimizing Your Capsule Loader Machine Procurement Process

-

Common Issues Faced by Businesses When Choosing Capsule Packaging Machines