Blog

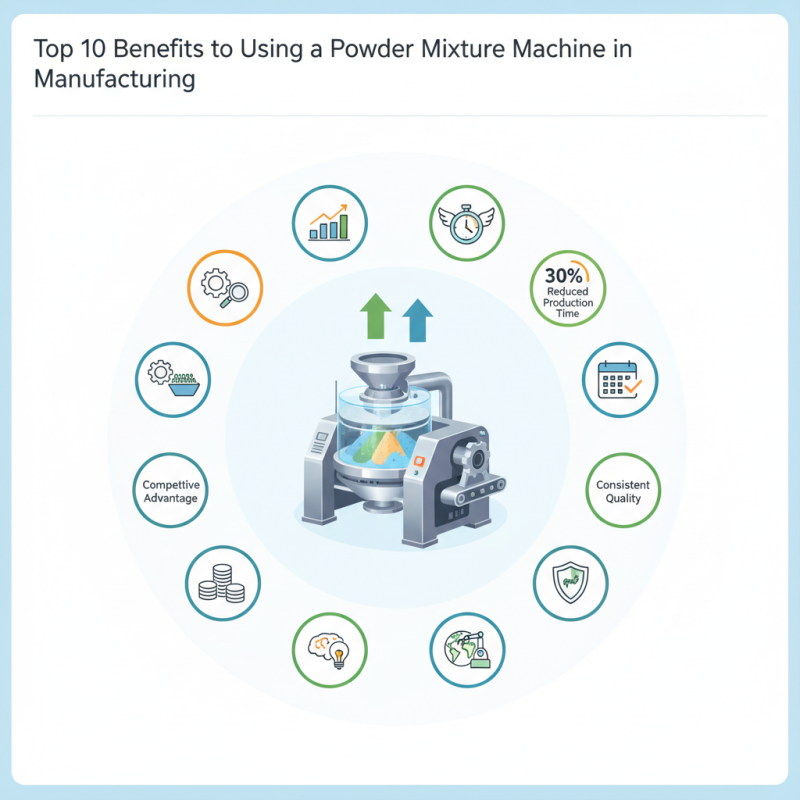

Top 10 Benefits of Using a Powder Mixture Machine in Manufacturing

In the fast-paced manufacturing industry, efficiency and precision are key to success. A **Powder Mixture Machine** provides significant advantages that many manufacturers overlook. According to industry reports, about 65% of manufacturers who integrated powder processing equipment saw productivity gains within six months. This machine enhances the mixing process, ensuring uniformity and quality in each batch produced.

Many manufacturers still rely on outdated blending methods. These traditional techniques can lead to inconsistencies and delays. For instance, non-automated processes often yield errors in ratios, affecting the final product's performance. The **Powder Mixture Machine**, however, offers automation and precision that manual methods cannot match.

Data indicates that companies using these machines report a 30% reduction in production time. This improvement translates to increased profitability and faster market delivery. However, some businesses remain hesitant to upgrade. They may worry about initial costs or the learning curve associated with new technology. As production demands grow, the need for efficient mixing solutions becomes undeniable. Investing in a **Powder Mixture Machine** could be the turning point for many manufacturers looking to thrive in a competitive landscape.

Benefits of Enhanced Mixing Efficiency in Powder Mixture Machines

In the manufacturing industry, enhanced mixing efficiency is crucial. Powder mixture machines revolutionize this process. According to industry reports, the right mixing technology can improve production rates by as much as 30%. This increase not only cuts costs but also enhances product consistency.

Consider the time savings associated with efficient mixing. Advanced machines can provide uniform blends in as little as five minutes. This rapid processing allows manufacturers to respond quickly to market demands. However, not all machines deliver the same efficiency. Some models may struggle with specific powder types, leading to subpar results. Manufacturers must assess their needs carefully.

Another important factor is reduced labor costs. Studies show that automated mixing systems can decrease manual labor by nearly 50%. While initial investments may be high, the long-term savings often justify this. Still, a machine's performance can vary widely based on maintenance and usage. Regular evaluations are necessary to ensure optimal efficiency over time. Ignoring this can lead to costly downtime.

Reduction of Production Time: Analyzing Cycle Time Improvements

The efficiency of manufacturing processes heavily relies on technology. A powder mixture machine can significantly reduce production time. According to industry reports, these machines can cut cycle times by up to 30%. This reduction is crucial for maintaining a competitive edge.

Faster mixing times lead to quicker production rates. A well-calibrated powder mixture machine ensures consistency, minimizing human error. Yet, some operations still rely on outdated practices. They miss out on the benefits of technology. In contrast, companies using modern machines report a 20% increase in output.

But not all machines deliver the same results. Some may require regular calibration and maintenance. This can introduce downtime, countering the benefits. Real-world case studies highlight that the right investment in machinery can pay off in reduced cycle times. Continual updates to the equipment are vital for optimizing production efficiency.

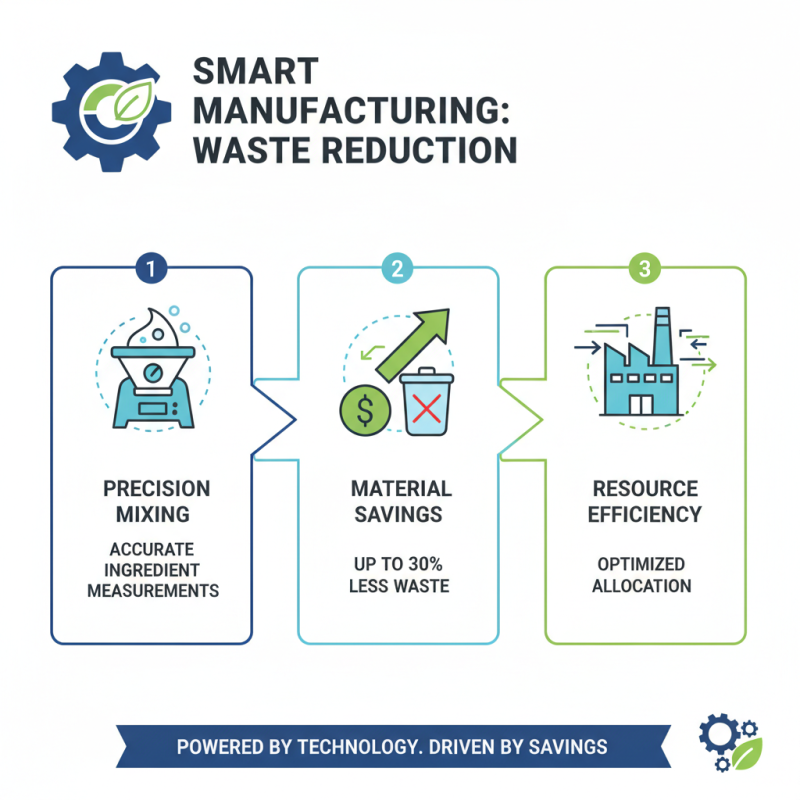

Minimizing Waste Through Precise Ingredient Measurements

In manufacturing, waste reduction is a critical concern. Using a powder mixture machine can effectively address this issue. Accurate ingredient measurements lead to significant savings. According to industry reports, businesses can reduce material waste by up to 30% with precise mixing technology. This enables manufacturers to allocate resources more efficiently.

Moreover, precise measurements allow for a consistent end product. Inconsistent mixing can lead to variations, affecting quality. An estimated 20% of manufacturing inefficiencies stem from inaccurate ingredient proportions. By using a powder mixture machine, manufacturers can minimize these discrepancies. This means better quality control and higher customer satisfaction.

Even with advanced machines, challenges remain. Calibration issues can occur, leading to potential waste. Regular maintenance is essential to ensure optimal performance. Without it, discrepancies may increase, negating the benefits of precision. Manufacturers must remain vigilant and adapt their processes for continual improvement. The battle against waste is ongoing, and precision is a crucial ally.

Cost Savings Through Bulk Material Processing Capabilities

The use of a powder mixture machine can lead to significant cost savings in manufacturing. By processing bulk materials, businesses reduce the need for multiple smaller machines. This shift not only streamlines operations but also cuts down labor costs. Imagine having one machine do the work of three. It’s more efficient and saves money.

Tips: Consider using machines that can handle different types of powders. This flexibility can further reduce costs. Additionally, think about maintenance. A well-maintained machine performs better and lasts longer. It’s worth investing time in upkeep to avoid costly repairs.

Moreover, sourcing bulk materials often brings discounts. Suppliers are likely to offer better pricing for larger orders. However, companies should evaluate their storage capacities. Overestimating needs can lead to waste and extra costs. Balancing purchase quantities with demand is crucial for maximizing savings.

Improving Product Quality: Consistency in End-Product Characteristics

Powder mixture machines play a crucial role in enhancing product quality in manufacturing. These machines ensure uniformity in the mixtures, which directly affects the final product. Consistency is vital. Variability can lead to defects and inconsistencies. A uniform mixture leads to a reliable end product.

In use, operators often face challenges. Dust generation can be a problem. This can compromise the quality of the mixture. Training is essential to minimize errors. Operators need to monitor the machines closely to maintain optimal performance. Sometimes, even the best equipment can fail to deliver expected results. Regular maintenance is crucial for keeping machines in top shape.

Additionally, different materials interact uniquely. This can lead to unexpected outcomes. Adjustments may be necessary to achieve the desired consistency. It's important to test mixtures frequently. Feedback loops can lead to continuous improvement. While the powder mixture machine offers many benefits, the potential for human error remains. Attention to detail is vital in this process.

Top 10 Benefits of Using a Powder Mixture Machine in Manufacturing - Improving Product Quality: Consistency in End-Product Characteristics

| Benefit | Description | Impact on Quality |

|---|---|---|

| Uniform Mixing | Ensures all ingredients are thoroughly mixed for consistent quality. | Improves product characteristics such as texture and flavor. |

| Increased Production Efficiency | Reduces mixing time compared to manual processes. | Enables consistent output quality with time savings. |

| Scalability | Easily accommodates varying batch sizes without impacting quality. | Consistent quality across different production scales. |

| Reduction in Human Error | Automated processes limit manual handling mistakes. | Enhances overall reliability and product integrity. |

| Improved Safety | Less physical handling of powders reduces accident risks. | Yields a safer working environment promoting quality focus. |

| Consistent Batch Quality | Maintains uniform quality across production batches. | Delivers reliability in product attributes such as taste and appearance. |

| Enhanced Output Control | Allows for adjustments to the mixing process in real time. | Ensures adherence to quality standards with flexibility. |

| Quality Assurance | Integrated quality checks throughout the mixing process. | Positive impact on end product reliability and customer satisfaction. |

| Reduced Waste | Minimizes material loss during mixing compared to manual methods. | Lower costs and higher quality by limiting variability. |

| Automatic Reporting | Tracks mixing parameters for further analysis. | Supports continuous improvement in product quality. |

Related Posts

-

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing

-

Exploring Unique Options for Mesin Mixer Powder in Industrial Applications

-

How the Best Powder Pulverizer Transforms Food Processing: Industry Case Studies and Insights

-

Ultimate Guide to Choosing the Best Powder Mixers for Your Business Needs

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs