Blog

Top Benefits of Using a Powder Milk Mixer for Effortless Mixing Solutions

In today's fast-paced food and beverage industry, efficient mixing solutions are crucial for ensuring product quality and consistency. The demand for powdered milk is rising, driven by consumer preferences for convenient and nutritious alternatives to traditional dairy products. According to a recent report by Grand View Research, the global powdered milk market is expected to reach USD 39.1 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.4%. This growth underscores the necessity for reliable equipment that can streamline production processes while maintaining high standards.

Recognizing the challenges associated with mixing powdered ingredients, many manufacturers are turning to advanced technologies such as the "Powder Milk Mixer." This innovative equipment not only improves mixing efficiency but also enhances the quality of the final product by ensuring uniform distribution of ingredients. Studies indicate that proper mixing can lead to a reduction in production time and an increase in final product consistency, ultimately resulting in higher customer satisfaction and reduced operational costs.

As the industry continues to evolve, investing in a Powder Milk Mixer proves to be an intelligent choice for businesses looking to improve their mixing operations and meet the growing consumer demand for powdered milk products.

Key Features of Powder Milk Mixers for Optimal Performance

When considering the key features of powder milk mixers for optimal performance, one must analyze aspects such as mixing efficiency, durability, and ease of use. A high-quality powder milk mixer should provide a consistent and thorough blend, ensuring that every batch is uniform in texture and flavor. Look for mixers with adjustable speed settings, as this allows users to fine-tune the mixing process according to their specific needs, ensuring the perfect consistency without clumps.

In addition to mixing efficiency, the construction of the mixer is vital. Durable materials not only enhance the lifespan of the machine but also promote safety during operation. Stainless steel components are often preferred due to their resistance to corrosion and ease of cleaning. Moreover, a well-designed mixer will have features like a secure lid to prevent spills, and an ergonomic design that makes it comfortable to operate for extended periods.

Tips: Always ensure that the mixer is properly calibrated before starting a new batch to prevent inconsistencies. Additionally, periodically check the seals and gaskets for wear and tear, as these can significantly affect the performance over time. Invest in a mixer with a user-friendly interface to make adjustments during the mixing process quick and intuitive, enhancing your overall experience.

Advantages of Using a Powder Milk Mixer in Various Industries

In various industries, the use of a powder milk mixer presents numerous advantages that enhance operational efficiency and product quality. One of the primary benefits is the consistent mixing of powdered milk with other ingredients, which is crucial in food production. Whether in infant formula manufacturing or nutritional supplements, a powder milk mixer ensures that the final product has uniform texture and flavor, thereby meeting stringent quality standards. This uniformity not only improves consumer satisfaction but also strengthens brand loyalty as customers increasingly seek reliable and high-quality products.

Furthermore, the versatility of powder milk mixers makes them suitable for a wide range of applications beyond the food industry. These mixers can be employed in pharmaceuticals for creating powdered medications or in cosmetics where powdered ingredients need to be blended effectively. Their ability to handle different types of powders without contamination enhances production flexibility and minimizes downtime. Additionally, the automation of mixing processes through these machines reduces labor costs and the risk of human error, ensuring that businesses can operate more efficiently while maintaining high-quality output.

Top Benefits of Using a Powder Milk Mixer

How Powder Milk Mixers Enhance Mixing Efficiency and Consistency

In the realm of food production and beverage blending, powder milk mixers stand out as essential tools for enhancing both mixing efficiency and consistency. These specialized mixers are designed to seamlessly integrate powdered milk with liquids, ensuring a uniform blend every time. By utilizing advanced mixing techniques such as vortexing or turbulence, these machines minimize clumping and create a smooth, creamy texture, which is crucial for maintaining quality in final products. This level of efficiency not only saves time but also reduces the labor required in the mixing process.

Moreover, the consistency achieved through the use of powder milk mixers is unparalleled. Consistent mixing is vital for mass production environments where variations can lead to discrepancies in taste and texture, potentially disappointing customers. With controlled mixing times and programmable settings, these mixers provide reliable results batch after batch. This reliability ultimately leads to reduced wastage and improved product quality, bolstering the overall reputation of producers in the competitive market. The streamlined process that powder milk mixers introduce transforms traditional mixing methods, making them a pivotal asset in any production facility focused on delivering high-quality dairy products.

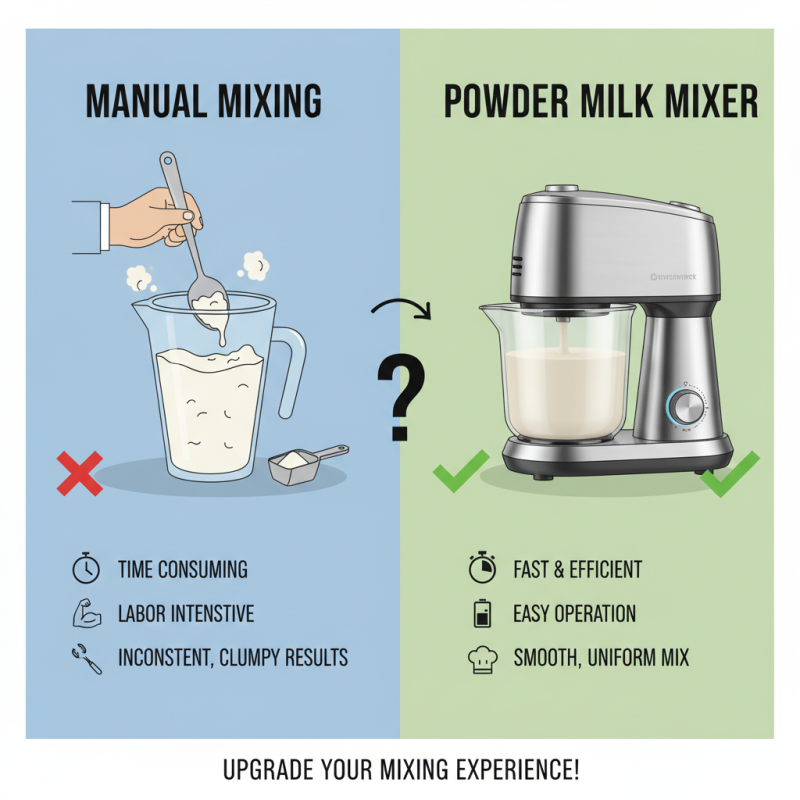

Comparative Analysis: Manual Mixing vs. Powder Milk Mixers

When it comes to mixing powdered milk, there are two primary approaches: manual mixing and the use of powder milk mixers. Manual mixing involves using basic utensils like scoops and spoons to blend the powder with liquid, a method that may seem straightforward but often yields inconsistent results. The process can be labor-intensive, requiring significant time and effort, especially when dealing with large volumes. Furthermore, achieving a uniform mixture can be challenging, leading to clumps that affect the texture and taste of the final product.

In contrast, powder milk mixers offer a more efficient and effective solution for achieving consistent mixes. These machines are designed to handle various types of powders, ensuring even distribution and proper hydration in a fraction of the time required for manual mixing. The advanced technology behind these mixers allows for customization in blending speeds and durations, resulting in finely mixed powder without lumps. This not only saves time but also enhances the quality of the final mix, making it an optimal choice for both commercial and home applications. The comparative analysis reveals that while manual mixing can suffice for small-scale needs, powder milk mixers stand out for their efficiency, consistency, and ease of use, especially in high-demand situations.

Maintenance Tips for Ensuring Longevity of Powder Milk Mixers

Proper maintenance of powder milk mixers is essential for ensuring their longevity and maintaining optimal performance. Research indicates that regular cleaning and inspection can significantly extend the lifespan of mixing equipment. According to a report by the Food and Beverage Manufacturing Association, neglecting proper care can lead to equipment malfunctions, which may result in unscheduled downtimes and costly repairs. Keeping the mixer free from residue buildup not only improves hygiene standards but also enhances the consistency of the mixed product.

Moreover, maintaining the motor’s reliability is crucial. Routine checks on the electrical components and lubrication of moving parts can prevent wear and tear and ensure that the mixer operates efficiently. A study published in the Journal of Food Engineering highlights that well-maintained mixers maintain higher operational speeds, reducing mixing times by up to 30%. Regularly scheduling maintenance and adhering to manufacturer guidelines can result in significant cost savings over the mixer’s lifecycle, making these practices vital for any operation relying on powder milk mixers.

Related Posts

-

Revolutionizing Infant Nutrition: The Science Behind the Powder Milk Mixer

-

Why You Need a Mixing Powder Machine for Your Manufacturing Success

-

Ultimate Guide to Selecting the Best Powder Mixture Machine for Your Needs

-

Understanding the Efficiency of Powder Mixers in Modern Manufacturing

-

Exploring Unique Options for Mesin Mixer Powder in Industrial Applications

-

What Is a Powder Mixture Machine and How Does It Revolutionize Material Processing?