Blog

2026 Top Capsules Filling Machine Trends and Innovations?

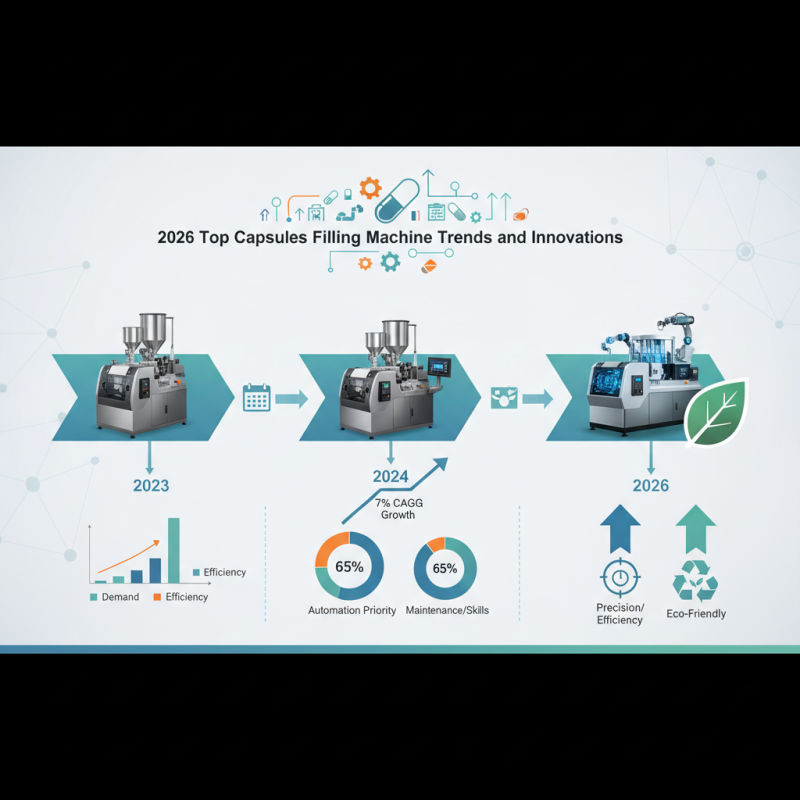

The global market for Capsules Filling Machines is witnessing a significant transformation. According to a recent market research report, the Capsules Filling Machine market is projected to grow at a compound annual growth rate (CAGR) of around 7% from 2023 to 2026. This growth is largely driven by rising demand in the pharmaceutical and nutraceutical sectors. Enhanced precision and efficiency are critical factors in this evolution.

Innovations in technology are shaping the capabilities of these machines. Features like automatic filling, adjustable speed control, and user-friendly interfaces are becoming standard. Data indicates that 65% of users prioritize automation in their purchasing decisions. However, the industry still faces challenges. Maintenance costs and the need for skilled operators can limit some companies' ability to invest in new machines.

As we look towards 2026, the landscape of Capsules Filling Machines is dynamic yet demanding. Companies must adapt to the rapid advancements to stay competitive. The focus on sustainable practices is also gaining momentum—often, products do not meet eco-friendly standards. Reflecting on these developments will be crucial for future progress.

2026 Innovations in Capsule Filling Machine Technology

The capsule filling machine industry is witnessing significant innovations in 2026. Technology is evolving rapidly, enhancing efficiency and precision in capsule production. Newer machines feature advanced automation, allowing operators to fill capsules faster and with less human intervention. This shift to automation can reduce errors but may also lead to less hands-on experience for workers.

Certain designs focus on adaptability. Machines now accommodate various capsule sizes without needing extensive reconfiguration. This flexibility is essential for companies that offer diverse products. However, with increased flexibility, there could be a learning curve for operators, necessitating training to fully leverage these advancements.

Tips: Embrace new technology, but don’t overlook the human element. Regular training for operators is crucial. Ensure they understand both the machine’s capabilities and its limitations. Pay attention to maintenance. Automated machines can still malfunction if not cared for properly. Regular checks will help prevent unexpected downtime.

The Rise of Automation in Capsule Filling Machines

The rise of automation in capsule filling machines is transforming the industry. Automation offers speed and efficiency, streamlining the manufacturing process. Machines can now fill hundreds of capsules each minute with minimal human intervention. This reduces labor costs and minimizes human error. However, it is not without challenges.

Many manufacturers are grappling with the initial investment required for automation. The costs can be daunting for smaller companies. Moreover, training staff to operate advanced machines is essential yet often overlooked. Engineers must also ensure that these automated systems are adaptable to various formulations. Flexibility in production is crucial, as demand for diverse products increases.

Despite these challenges, automation paves the way for quality assurance. Automated machines can monitor the filling process, ensuring precise dosages. This technology can lead to fewer recalls and higher consumer trust. However, the industry must remain vigilant. Over-reliance on machines may impact craftsmanship and attention to detail. Balancing automation with human oversight will be vital for future success.

Eco-Friendly Materials in Capsule Filling Equipment

The trend towards eco-friendly materials in capsule filling equipment is gaining momentum. Manufacturers are increasingly adopting biodegradable and recyclable components. This shift responds to growing consumer demand for sustainable options. Eco-conscious practices can reduce environmental footprints significantly. Yet, implementing these materials poses challenges.

For example, biodegradable plastics may not provide the same durability as traditional options. This raises concerns about the safety and efficacy of encapsulated products. Finding a balance between sustainability and performance is crucial. Companies must evaluate the lifecycle of materials used. Some innovations may need refinement to ensure they meet industry standards.

Another area to consider is sourcing. Sustainable materials often come with higher costs. Not all manufacturers are ready to invest in eco-friendly alternatives. The transition requires careful planning and resources. Despite the hurdles, the potential benefits are vast. Better materials can enhance brand reputation and customer trust. Reflection on these aspects is essential for driving meaningful change in the industry.

2026 Capsule Filling Machine Trends and Innovations

This chart illustrates the key trends and innovations in capsule filling machines for 2026, highlighting the increasing focus on eco-friendly materials and automation. Eco-friendly materials are projected to dominate the market with 35%, while automation and customizable sizes follow behind.

Enhancements in Precision and Speed for Filling Processes

The advancements in capsule filling machines are transforming the industry. Precision has become paramount. Manufacturers are exploring new technologies to improve accuracy in filling capsules. Modern machines can achieve a filling precision rate exceeding 99%. This high level of accuracy minimizes waste and ensures product consistency.

Speed is another critical factor. Faster filling processes are essential for meeting rising market demands. New designs achieve higher throughput without sacrificing quality. Some machines now operate at speeds up to 300 capsules per minute. This enhancement aligns with the industry's trend to shorten production cycles.

Tips:

Evaluate your current filling processes. Identify areas where precision may lag. Small adjustments can make a significant impact.

Keep an eye on maintenance checks. Regular servicing can prevent speed losses. Machines cannot perform optimally without proper care.

Incorporating these innovations requires thoughtful consideration. Teams must reflect on how changes impact workflow. Balancing speed and precision is vital for long-term success.

Market Trends Influencing Capsule Filling Technology Advancements

The capsule filling machine market is rapidly evolving. Current trends show an increased demand for automation and precision. Reports indicate that the global capsule filling machine market is projected to reach $3.7 billion by 2026, growing at a CAGR of 7.2%. This growth is driven by the rise in the nutraceutical and pharmaceutical industries. Companies are focusing on advanced technologies that enhance efficiency and reduce human error.

Sustainability is another key factor influencing innovation. Many manufacturers are adopting eco-friendly materials for capsule production. Additionally, there is a growing interest in custom capsule designs to cater to specific consumer preferences. Data suggests that personalized supplements are gaining traction, prompting a shift towards more flexible filling machines. Yet, some challenges exist, such as the higher costs of these advanced systems. Market players must balance innovation with affordability.

Interestingly, regulatory complexities can slow down the adoption of new technologies. While advancements are crucial, meeting stringent quality standards remains a priority. Manufacturers are investing in R&D to ensure compliance. However, ensuring scalability of these innovations often poses dilemmas. As a result, the push for cutting-edge solutions can sometimes overlook practical implementation. An ongoing dialogue in the industry is needed to address these concerns effectively.

2026 Top Capsules Filling Machine Trends and Innovations

| Trend/Innovation | Description | Impact on Market | Projected Growth (%) |

|---|---|---|---|

| Automation Integration | Incorporation of robotic systems for precise capsule filling | Increases efficiency and reduces labor costs | 15% |

| Eco-friendly Materials | Use of biodegradable and sustainable capsule materials | Appeals to environmentally conscious consumers | 10% |

| Personalized Medicine | Tailoring capsule formulations based on patient needs | Enhances patient adherence and satisfaction | 12% |

| AI and Data Analytics | Utilization of AI for predictive maintenance and quality control | Minimizes downtime and improves production consistency | 20% |

| High-speed Filling Technology | Advancements in machinery to boost filling speeds | Satisfies growing demand without sacrificing quality | 18% |

Related Posts

-

What is a Capsules Filling Machine? Benefits, Types, and How It Works

-

How to Choose the Right Capsules Filling Machine for Your Production Needs

-

Revolutionizing Your Production Line: The Ultimate Guide to Capsules Filling Machines

-

Top Capsules Filling Machines of 2025 for Efficient Pharmaceutical Production

-

Common Issues Faced by Businesses When Choosing Capsule Packaging Machines

-

7 Best Capsule Packaging Machines for Enhanced Efficiency in 2023